CITY OF SACRAMENTO

STANDARD

SPECIFICATIONS

FOR PUBLIC CONSTRUCTION

November 2020

STANDARD

SPECIFICATIONS

FOR PUBLIC CONSTRUCTION

City of Sacramento

California

Adopted by City Council

November 2020

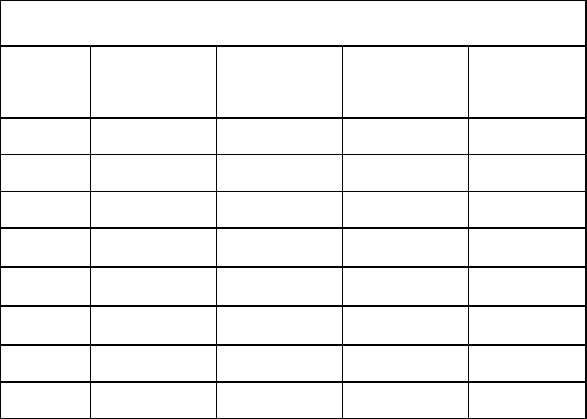

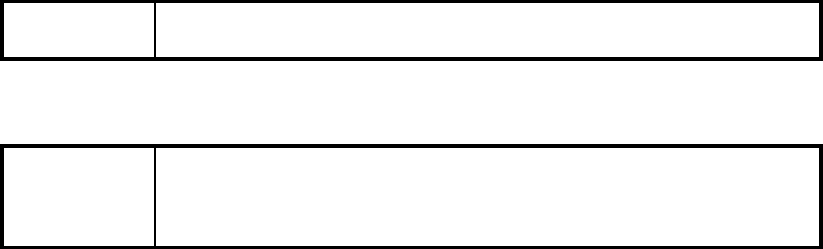

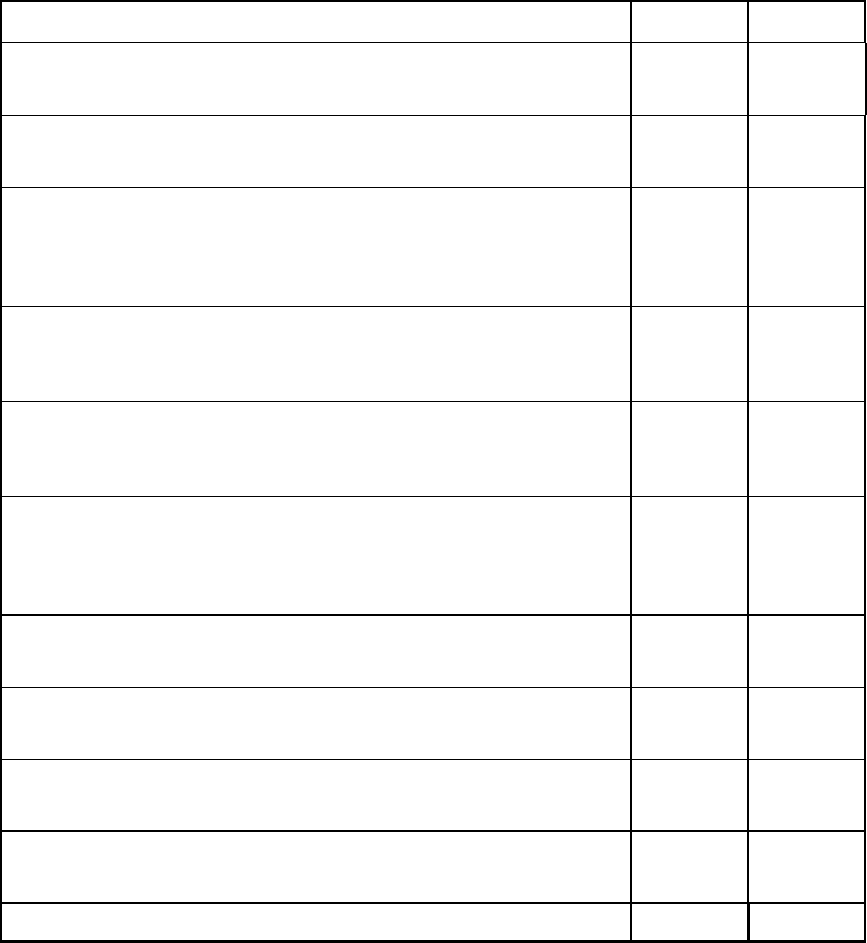

TABLE OF CONTENTS

Section Title Pages

Section 1 Definitions and Terms 1-1 to 1-6

Section 2 Bid/Proposal Requirements and Conditions 2-1 to 2-6

Section 3 Award and Execution of Contract 3-1 to 3-3

Section 4 Scope of Work 4-1 to 4-8

Section 5 Control of Work and Materials 5-1 to 5-12

Section 6 Legal Relations and Responsibilities to the Public 6-1 to 6-17

Section 7 Prosecution and Progress 7-1 to 7-7

Section 8 Measurement and Payment 8-1 to 8-7

Section 9 Reserved 9-1

Section 10 Construction Materials 10-1 to 10-55

Section 11 Preconstruction Photographs 11-1 to 11-2

Section 12 Clearing and Grubbing, Tree Removal 12-1 to 12-2

Section 13 Existing Facilities 13-1 to 13-5

Section 14 Earthwork, Excavation, Embankment and Sub-grade 14-1 to 14-8

Section 15 Water Used in Construction 15-1 to 15-2

Section 16 Water Quality Control 16-1 to 16-6

Section 17 Laying Aggregate Base 17-1 to 17-3

Section 18 Headers 18-1 to 18-2

Section 19 Portland Cement Concrete Pavement, Joints and Curing 19-1 to 19-4

Section 20 Concrete in Structures 20-1 to 20-15

ii

TABLE OF CONTENTS

Section Title Pages

Section 21 Placing Steel Reinforcement 21-1 to 21-4

Section 22 Asphaltic Concrete 22-1 to 22-11

Section 23 Bituminous Seal 23-1 to 23-13

Section 24 Curbs, Gutters, and Sidewalks 24-1 to 24-5

Section 25 Sanitary Sewer and Drainage Manholes 25-1 to 25-7

Section 26 Laying Sewer and Drain Pipe 26-1 to 26-24

Section 27 Water Distribution Systems 27-1 to 27-37

Section 28 Driveway Culvert and Sidewalk French Drains 28-1 to 28-3

Section 29 Moving or Changing Utilities and Water Services 29-1

Section 30 Drain Inlets, Gutter Drains and Ditch Boxes 30-1

Section 31 Construction of Chain Link Fence 31-1 to 31-2

Section 32 Traffic Signs, Markings and Barricades 32-1 to 32-10

Section 33 Pneumatically Applied Mortar 33-1 to 33-4

Section 34 Electrical 34-1 to 34-15

Section 35 Landscape Planting 35-1 to 35-24

Section 36 Irrigation System 36-1 to 36-8

Section 37 Boring and Jacking 37-1 to 37-6

Section 38 Standard Drawings 38-1 to 38-10

Index i-1 to i-14

1-1

Section 1

DEFINITIONS AND TERMS

Unless expressly indicated otherwise, the following terms or abbreviations used

in these Specifications, or in any other Contract Documents, are defined as follows:

1-1 “A.A.S.H.T.O.” The American Association of State Highway and

Transportation Officials.

1-2 “Addendum” means a document issued prior to the execution of the

Agreement, that modifies or interprets any of the Contract Documents,

by additions, deletions, clarifications, or corrections.

1-3 “Agreement” means the written agreement executed by Contractor and

City, that constitutes one of the Contract Documents.

1-4 “A.S.T.M.” The American Society for Testing Materials.

1-5 “A.W.W.A.” The American Water Works Association.

1-6 “Bid” means a response to a request or invitation for bids or proposals. A

“formal” Bid means a Bid submitted for a Contract required to be awarded

by the Sacramento City Council pursuant to the Sacramento City Code,

and “formal” bidding means the bidding process used for such Contracts.

1-7 “Bid Form” means the approved form upon which the City requires formal

Bids for the Work to be prepared and submitted.

1-8 “Bid Security” means the bid security furnished by the Bidder as a

guarantee of good faith that it will enter into a Contract and execute the

required Bonds covering the Work if awarded the Contract.

1-9 “Bidder” means any individual, partnership, corporation, or other entity

or combination thereof, submitting a Bid, whether acting directly or

through a duly authorized representative.

1-10 “Change Order” means an amendment to a Contract issued after the

effective date of the Contract.

1-11 “City” means the charter municipal corporation known as the City of

Sacramento, in the State of California.

1-2

1-12 “City Council” means the City Council of the City of Sacramento or any

other board, body, official or officials, to which or to whom the power

belonging to the City Council may pass.

1-13 “City Manager” means the City Manager of the City of Sacramento acting

either directly or through properly authorized representatives acting

within the scope of their authorized duties.

1-14 “Completion Date” means the date for completion of the entire Work as

defined in Section 9 of the Agreement.

1-15 “Contract” shall mean the written Contract Documents covering the

performance of the Work including the furnishing of labor, materials,

tools, and equipment.

1-16 “Contract Documents” means the various documents that make up the

Contract, which are identified in Section 1 of the Agreement.

1-17 “Contract Price” means the total dollar amount of the Contract.

1-18 "Contractor” means the individual, partnership, corporation, or other

entity or combination thereof, or its duly authorized representative, that

has entered into a Contract with the City.

1-19 “Controlling Operation” means an item of Work on the project’s critical

path whose duration time directly affects the date that the entire Work

can be completed.

1-20 “Critical Path Method Schedule” or “CPM Schedule” means a schedule

with a consecutive sequence for completion of the Work with the least

amount of float period(s).

1-21 “Day” means a working day, unless otherwise expressly defined in the

Special Provisions.

1-22 “Date of signing” means the date upon which the Contract, properly

executed by Contractor and delivered to the City, was executed by the

City.

1-23 “Director” means the Director of the City Department administering the

Contract.

1-24 “Division Manager” means the Division Manager of the City department

and division administering the Contract, or other City employee

1-3

designated by such Division Manager to perform any duties assigned to the

Division Manager in these Specifications.

1-25 “Engineer” means the Director, the Director’s subordinates, or other City

representative(s) who have been duly authorized to exercise control and

supervision of the Work. The Engineer typically is, but is not required to

be, either a professional engineer architect, or landscape architect,

depending on the nature of the Work.

1-26 “Federal Specifications” means the Standard Specifications of the United

States Government designated in the Contract Documents.

1-27 “Field Order” means a written instruction from the Engineer to

Contractor made in the field.

1-28 “Finance Director” means the Director of the Department of Finance of

the City of Sacramento and includes the “City Controller” as used in the

Sacramento City Charter.

1-29 “Fixed cost” means a cost that remains constant regardless of the

quantity of work done.

1-30 “Float period” means such period(s) of time as may be shown on

Contractor’s schedule(s) that are not allocated to the performance and

completion of the Controlling Operation(s) of the Work.

1-31 “Inspector” means an engineering or construction inspector acting within

the authorized scope of the particular duties and authority delegated to

such inspector by the City.

1-32 “Laws or Regulations” means any and all applicable laws, rules,

regulations, ordinances, codes, resolutions, requirements and/or orders

of any and all governmental bodies, agencies, authorities and courts,

including but not limited to provisions of the Sacramento City Charter and

City Code.

1-33 “LBE participation” means participation in performance of the Work by

Local Business Enterprises in accordance with the provisions of Article VIII

of Chapter 3.60 of the Sacramento City Code and the policies and

procedures adopted to implement those provisions.

1-34 “Liquidated damages” means the sum or sums prescribed in the Contract

Documents, pursuant to the authority of Government Code Section

53069.85, to be paid to the City or to be deducted from any payment due

or to become due to Contractor for delay beyond the time allowed in the

1-4

Contract Documents for completing the whole, or any specified portion,

of the Work.

1-35 “Landscape Architect” means a Landscape Architect of the City of

Sacramento assigned to the Work.

1-36 “Payment Bond” has the same meaning as in Section 3096 of the California

Civil Code, and refers to the approved form of security furnished by

Contractor and its Surety to guarantee the payment in full of all bills,

accounts and related costs for labor and materials used in construction of

the Work.

1-37 “Performance Bond” means the approved form of security furnished by

Contractor and its Surety to guarantee Contractor’s performance and

completion of the Work in accordance with the terms of the Contract.

1-38 “Plans” means the official Project Plans and Standard Drawings, profiles,

typical cross sections, general cross sections, working drawings and

supplemental drawings, or reproductions thereof, approved by the

Director, that show the location, character, dimensions and details of the

work to be performed. All such documents are part of the Plans whether

or not reproduced in the Special Provisions. In this definition, the terms

“Standard Drawings” and “Project Plans” mean:

(1) “Standard Drawings”: The Standard Drawings or Standard Drawing as

set forth in these Specifications. “Standard Drawing(s)” means

“Standard Detail(s)”.

(2) “Project Plans”: The Project Plans or Plans include specific details and

dimensions peculiar to the Work and that are supplemented by the

Standard Drawings as they may apply.

1-39 “Project Estimate” means the list of estimated quantities of Work to be

performed that is included in the Notice to Contractors

1-40 “Proposal” means the offer of the Bidder, including a Bid, for performance

and completion of the Work when properly completed, executed,

guaranteed and submitted on the Bid form.

1-41 “Special Provisions” means the specific clauses setting forth conditions or

requirements peculiar to the Work and supplementary to these

Specifications.

1-42 “Specifications” means the directions, provisions, and requirements

contained herein. In the Contract Documents, including the Special

1-5

Provisions, these Specifications may also be referred to as the “Standard

Specifications”.

1-43 “State Specifications” means the Standard Specifications of the State of

California, Department of Transportation, as currently approved and in

effect and as thereafter amended or renumbered.

1-44 “Subcontractor” means any person or firm of any tier directly or indirectly

utilized by Contractor to perform any portion of the Work.

1-45 “Substantially complete” means that the Engineer has determined that all

of the Work has been performed, but there are minor deficiencies, as

determined by the Engineer, that do not prevent the Work from being

fully functional nor pose any risk to the public health, safety or welfare

or public or private property, as determined by the Engineer. The Work

shall be considered substantially complete on the date that the Engineer

issues a punch list to Contractor as specified in Section 8-4 of these

Specifications.

1-46 “Supplier” means any person or firm directly or indirectly supplying any

materials or equipment for performance of, or incorporation in, the Work.

1-47 “Work” means all actions and activities that Contractor is contractually

required to undertake and perform as specified, indicated, shown, or

implied in the Contract, including all duly authorized Change Orders.

1-48 “Working day” means any day, except for the following:

(1) Saturdays, Sundays and legal holidays, unless otherwise indicated in

the Special Provisions.

(2) Days on which Contractor is prevented from proceeding with the

current Controlling Operation(s) of Work for at least (5) hours per day

due to inclement weather, or conditions resulting immediately

therefrom, as determined by the Engineer.

(3) Days on which Contractor is specifically required pursuant to the

Contract Documents or by operation of law to suspend the Controlling

Operation or Operations of Work, except in cases where such

requirement applies due to the failure on the part of Contractor or any

Subcontractor to carry out orders or to perform any provision of the

Contract.

2-1

Section 2

BID/PROPOSAL REQUIREMENTS AND CONDITIONS

2-1 NOTICE TO CONTRACTORS

“Notice to Contractors” is published by the City Clerk for formally bid

contracts in accordance with Article III of Chapter 3.60 of the Sacramento City

Code. Among other provisions, the Notice to Contractors makes reference to

Section 1770 et seq. of the Labor Code relating to determinations regarding

prevailing wages. Contractor shall pay prevailing wages according to the rates

established by these determinations. Copies of these determinations are on file

in the Office of the Director and shall be made available to any interested party

on request, and also may be retrieved from the internet at www.dir.ca.gov/dlsr.

A summary of the labor compliance requirements will be presented at

the pre-construction meeting. Each contractor and subcontractor (at all

levels/tiers) is required to submit certified payrolls and labor compliance

documentation electronically at the discretion of and in the manner specified

by, the City of Sacramento.

Electronic submittal will be through a web-based system, accessed on

the World Wide Web by a web browser.

Use of the system may entail additional data entry of weekly payroll

information including; employee identification, labor classification, total

hours worked and hours worked on this project, wage and benefit rates paid,

etc. The contractor’s payroll and accounting software may be capable of

generating a ‘comma delimited file’ that will interface with the software. If

the ‘comma delimited file’ option does not work, it is still the responsibility

of the contractor and subcontractors to manually enter their data into the

system specified by City of Sacramento, meeting the required deadlines for

those documents.

Every lower-tier subcontractor and vendor is required to provide labor

compliance documentation.

2-2 BID FORM

A Bid Form shall be made available to each prospective Bidder.

2-2

2-3 PROJECT ESTIMATE

The quantities included in the Project Estimate in the Notice to

Contractors, Bid Form and Contract are approximate only, and are given as a

basis for comparison of Bids. The City does not, expressly or by implication,

represent or agree that the actual amount of Work will equal the approximate

estimate. The City reserves the right to increase or decrease the amount of any

class or portion of the Work, or to omit portions of the Work, as may be deemed

necessary or advisable in the sole discretion of the Engineer, as provided in the

Contract Documents.

2-4 EXAMINATION OF CONTRACT DOCUMENTS AND SITE OF WORK

All Bidders shall carefully inspect the site of the contemplated Work, and

carefully review the Plans, Specifications, the Proposal and the other Contract

Documents. The submission of a Bid is conclusive evidence that the Bidder has

investigated and is satisfied as to the conditions to be encountered, the

character, quality, quantity and scope of Work to be performed, the quantities

of materials to be furnished, and the requirements of the Contract Documents,

and that the Bidder is aware of no material discrepancy between such conditions,

the character, quality, quantity and scope of Work to be performed, the

quantities of materials to be furnished, and the requirements of the Contract

Documents. If the Engineer has made investigations of conditions in areas where

the Work is to be performed or in other areas, some of which may constitute

possible local material sources, such investigations are made only for the purpose

of study and design. Subject to and upon the conditions set forth below, where

such investigations have been made, prospective Bidders or Contractor may,

upon written request, inspect the records of such investigations. Any inspection

of the records shall be made at such place or places that may be specified in the

Special Provisions or by the Engineer.

The records of such investigations are not part of the Contract and are

shown solely for the convenience of prospective Bidders or Contractor. The

Engineer and the City assume no responsibility whatsoever in respect to the

sufficiency or accuracy of such investigations, the records of the investigation,

or any interpretation in the investigation or made by the Engineer and that there

is no representation, warranty or guarantee, either express or implied, that the

conditions indicated by such investigations or records of the investigations are

representative of those existing throughout such areas, or any part thereof, or

that unanticipated developments may not occur, or that materials other than or

in proportion different from those indicated, may not be encountered.

The availability for use of information described in this Section is not a

waiver of the provisions of the first paragraph of this Section and all prospective

Bidders and Contractor are cautioned to make such independent investigations

2-3

and examinations as each of them may consider necessary to sufficiently inform

itself as to the conditions to be encountered in the performance of the Work,

and, with respect to possible local material sources, the quality and quantity of

material available from such sources and the type and extent of processing that

may be required in order to produce material conforming to the requirements of

the Contract. No information derived from such inspection of records of

investigations or interpretations made by the Engineer relieves any prospective

Bidder or Contractor from any risk or from properly fulfilling the terms of the

Contract.

2-5 PREPARATION OF PROPOSAL

Bid Forms and the plans and specifications are available on the City’s

website. Bids not presented on the Bid form shall be rejected.

Proposals must set forth in clearly legible figures, an item price and a

total for each item in the respective spaces provided, and must be signed by the

Bidder, who shall fill out all blanks in the Bid Form.

2-6 DETERMINATION OF AMOUNT BID – MATHEMATICAL ERROR

In determining the amount bid by each Bidder, the City may disregard

computations that contain obvious mathematical errors in addition, subtraction,

multiplication, and division that appear on the face of the Proposal. When such

a computational error appears on the face of the Proposal, the City may, but is

not obligated to correct any such error and compute the total amount bid by said

Bidder on the basis of the corrected figure or figures to determine which Bidder

has submitted the lowest bid. However, the City has no responsibility or liability

to any bidder if the City determines which Bidder has submitted the lowest bid

without doing so.

When an item price is required to be set forth in the Proposal, and the

total price for the item is not consistent with the figure that is derived by

multiplying the item price by the Project Estimate of the quantity of work to be

performed for said item, the item price shall prevail over the total price for the

item. The total to be paid for each item shall be based upon the item price and

not the total price for the item. If the Proposal contains only a total price for

the item, and not the item price, the City shall determine the item price by

dividing the total price for the item by the stated Project Estimate of the

quantity of work to be performed for the item.

If the Proposal contains neither the item price nor the total price for the

item, then it shall be deemed non-responsive and will be rejected.

2-4

2-7 REJECTION OF PROPOSALS

Proposals may be rejected if they show any alteration of form, additions

not called for, mathematical errors, conditional Bids, changes that make the

Proposal illegible, or contain irregularities.

When Proposals are signed by an agent, other than an officer or officers

of the corporation authorized to sign contracts on its behalf or a member of a

partnership, a “power of attorney” must be filed with the City of Sacramento

prior to opening Bids or submitted with the Proposal; otherwise, the Proposal

shall be rejected as non-responsive. The City reserves the right to waive any

informalities or minor irregularities in the Bids.

2-8 BID SECURITY

All Bids shall be accompanied by one of the following forms of Bidder’s

security: Cashier’s check, a certified check, or a Bidder’s Bond executed by a

surety insurer admitted and duly authorized to transact business in the State of

California, made payable to the City.

No Bidder’s Bond shall be accepted unless it substantially conforms to the

Bond form included in the Special Provisions. Bidder’s Bond forms may be

obtained from the Engineer. The Engineer may waive the requirement to furnish

Bid Security for Contracts that may be awarded without City Council approval

pursuant to the Sacramento City Code.

2-9 SUBCONTRACTORS

Each contractor or subcontractor performing any work for the City of

Sacramento, must be currently registered with the California Department of

Industrial Relations (DIR), as specified in Labor Code Section 1725.5. Labor Code

Section 1771.1 (enacted by SB 854) provides that a Contractor or subcontractor

is not qualified to bid on, or be listed in a Proposal (subject to the requirements

of Section 4104 of the Public Contract Code), or engage in the performance of

any Work, unless currently registered and qualified pursuant to Labor Code

Section 1725.5.

In addition, each Bidder and each Contractor shall, to the extent required

by law, comply with to the Subletting and Subcontracting Fair Practices Act of

the State of California (Public Contract Code Sections 4100 et seq.) and shall, in

the Bid, on a form provided by the City, set forth:

1. The name and location of the place of business and the California

contractor license number for each proposed Subcontractor who shall

perform work or labor or render service to the prime Contractor in or

2-5

about the construction of the Work, or a Subcontractor licensed by the

State of California who, under a subcontract to the prime Contractor,

specially fabricates and installs a portion of the Work or improvement

according to detailed drawings contained in the Plans and Specifications,

in an amount in excess of one-half of one percent of the prime

Contractor’s total bid or, in the case of bids for the construction of streets

or highways, including bridges, in excess of one-half of one percent of the

prime Contractor’s total bid or $10,000, whichever is greater.

2. The portion and dollar amount of the work that will be done by

each such Subcontractor. The prime Contractor shall list only one

Subcontractor for each such portion as is defined by the prime

Contractor in the Bid.

3. Every Bidder shall list the Contractor’s current DIR registration

number and the current DIR registration number of all listed

subcontractors, on the Subcontractor and Local Business Enterprise

(LBE) Participation Verification Form included in the contractor’s

bid.

In addition to the above requirements, Contractor shall perform with its

own organization and with the assistance of workers under its immediate

superintendence, work of a value not less than twenty percent (20%) of the value

of all Work in the Contract. The dollar amount of subcontracted work that is

specifically indicated by the Bidder on the form provided by the City shall be

used to determine the value of work being subcontracted, as well as the value

of LBE Subcontractor participation for purposes of determining compliance with

LBE participation requirements, unless the Engineer determines such value to be

significantly misstated. The Bidder shall provide such bidding information as may

be requested by the Engineer to make this determination.

2-10 SUBMISSION OF PROPOSAL

The Proposal shall be submitted as directed in the Notice to Contractors

in a sealed envelope provided by the City. The Bidder shall plainly mark the

exterior of the envelope in which the Proposal is submitted to indicate that it

contains a proposal for the project for which the proposal is submitted, and the

date of the Bid opening therefor. Proposals submitted in envelopes that are not

properly marked may be rejected. The Proposal cannot be withdrawn or

modified after the time specified for opening of the Bids, except as may be

authorized under Section 2-12 below.

2-6

2-11 PUBLIC OPENING OF PROPOSALS

Proposals shall be opened and read publicly at the time and place

indicated in the Notice to Contractors. Bidders or their authorized agents may

be present.

2-12 RELIEF OF BIDDERS

A Bidder may request relief from its Bid, pursuant to the provisions of

Public Contract Code Section 5100 et seq.

2-13 DISQUALIFICATION OF BIDDERS

City shall not consider more than one Proposal from an individual,

partnership, corporation, or other entity or combination thereof, under the same

or different names. If City has reasonable grounds to believe that any individual,

partnership, corporation or combination thereof is interested in more than one

Proposal as a prime Bidder for the work contemplated, City may reject all

Proposals in which such individual, partnership, corporation or combination

thereof is interested. If City has reason to believe that collusion exists among

any Bidders, City may reject the Proposals. City may reject a Proposal in which

the bid(s) submitted for one or more items are obviously unbalanced, as

reasonably determined by City.

2-14 LICENSING OF BIDDERS

All Bidders and Contractors shall be licensed in accordance with the laws

of California and any Bidder or Contractor not so licensed is subject to the

penalties imposed by such laws. The Bidder’s or Contractor’s license must be of

a class that permits its holder to do the Work contemplated as of the date the

Proposal is submitted and such license must be maintained for the duration of

the work. The Bidder shall indicate its license number and class in the space

provided for that purpose on the Bid Form.

The City shall specify the classification of license that a Contractor must

possess at the time a Contract is awarded. This shall be included in the Plans

and Notice to Contractors (Public Contract Code Section 3300).

2-15 PREQUALIFICATION OF BIDDERS

The City may establish prequalification requirements for Bidders on one

or more Contracts consistent with applicable provisions of the City Code, and

other applicable laws or regulations. The City may establish prequalification

requirements for Bidders on one or more Contracts consistent with applicable

provisions of the City Code, and any other Laws or Regulations if applicable.

2-7

2-16 JOINT VENTURE BIDS

If two or more prospective Bidders desire to bid as a joint venture on a

project, the prospective Bidders must first file an affidavit of joint venture with

the City on a form approved by the Engineer. The affidavit of joint venture is

valid only for the specific project for which it is filed. If an affidavit of joint

venture is not filed and approved by the Engineer prior to Bid opening, the joint

bid shall be rejected. On projects for which pre-qualification is required, each

party to the joint venture must separately pre-qualify in order to file a joint

venture affidavit. Joint venture bidders must comply with the California

Business and Professions Code, sections 7029 and 7029.1. A joint venture is not

required to have a current DIR registration number until after contract award,

so long as the prospective partners in the joint venture each have current DIR

registration numbers at the time of Bid opening. And a joint venture shall not be

qualified as a Local Business Entity unless the prospective partners in the joint

venture would separately qualify as Local Business Entities at the time of bid

opening.

2-17 AGREEMENT TO ASSIGN

If a Bid is accepted, the Bidder will assign to City all rights, title, and

interest in and to all causes of action it may have under Section 4 of the Clayton

Act (15 U.S.C. Sec. 15) or under the Cartwright Act, Chapter 2 (commencing with

Section 16700) of Part 2 of Division 7 of the Business and Professions Code),

arising from purchases of goods, materials, or services by the Bidder pursuant to

the Contract. The assignment is effective at the time the City tenders final

payment to the Bidder without further acknowledgement by the parties (Cal.

Govt. Code §4552).

2-18 COMMUNITY WORKFORCE TRAINING AGREEMENT COMPLIANCE

If the Engineer’s estimate for a project or the actual Contract awarded

exceeds $1,000,000, the City’s Local Hire and Community Workforce Training

Program and the City’s Community Workforce Training Agreement (CWTA) apply.

By submitting a Proposal for such a project, the Contractor acknowledges

that it has read and understands all the requirements, terms, and conditions of

the CWTA and CWTA Summary attached to the request or invitation for bids or

proposals (or otherwise available from the City), and has included all costs

associated with compliance with the CWTA in its Bid.

If the CWTA applies, the Contractor must execute Addendum A to the

CWTA (“Agreement to be Bound”) and provide an executed original to the City

before the Contract can be awarded. Each subcontractor for Work covered by

the CWTA, including subcontractors not listed at the time of bid or otherwise

2-8

hired after contract award, must also execute Addendum A to the CWTA. No

Contractor or subcontractor may perform Work prior to executing Addendum A

and providing the executed original to the City. The failure to sign and submit

Addendum A by the Contractor, shall be grounds for awarding the Contract to

another bidder. The failure to sign and submit Addendum A by any subcontractor

shall be grounds for subcontractor substitution and/or for the City to withhold

payment for the Work performed in the absence of the necessary Addendum A.

Contractor must include the provisions of this section, as well as a copy

of the CWTA and the CWTA Summary, in every subcontract for Work covered by

the CWTA. By submitting a bid, Contractor represents that if the bid amount

exceeds $1,000,000, the Contractor and all its subcontractors performing Work

covered by the CWTA will execute the Agreement to be Bound if awarded the

contract.

The failure to submit an Addendum A or to otherwise comply with the

requirements of the CWTA on this project may also result in a future

determination that the Contractor and/or subcontractor is not responsible

(pursuant to City Code section 3.60.020) when bidding on future projects for the

City of Sacramento.

3-1

Section 3

AWARD AND EXECUTION OF CONTRACT

3-1 AWARD OF CONTRACT

Unless otherwise provided in the Special Provisions, or otherwise

authorized by the City Council in accordance with applicable provisions of the

Sacramento City Code, the award of a formally bid Contract, if it is awarded, will

be to the lowest responsible Bidder (as defined in section 3.60.020 of the

Sacramento City Code) whose Bid complies with the specific requirements of the

Contract Documents. The City Council reserves the right to reject any and all

Proposals.

3-2 TIME OF AWARD

The award of a formally bid Contract, if made, will be made within sixty

(60) calendar days after the opening of the Proposals.

If the lowest responsible Bidder refuses or fails to execute the Contract,

the City Council may award the Contract to the second lowest responsible Bidder.

Such award, if made, will be made within ninety (90) calendar days after the

opening of Proposals.

If the second lowest responsible Bidder refuses or fails to execute the

Contract, the City Council may award the Contract to the third lowest

responsible Bidder. Such award, if made, will be made within one hundred and

twenty (120) calendar days after the opening of the Proposals.

The periods of time specified above within which the award of the

Contract may be made, may be extended by written agreement between the

Engineer and the applicable Bidder.

3-3 COMPARISON OF BIDS

All Bids shall be compared on the basis of the Project Estimate of

quantities of Work to be done, with such corrections in mathematical errors

appearing on the face of the Proposal as the City may choose to make pursuant

to Section 2-6 of these Specifications.

3-4 PERFORMANCE AND PAYMENT BONDS

The successful Bidder shall provide Performance and Bonds to the City,

each for a sum equal to one hundred percent (100%) of the Contract Price. Each

3-2

Bond shall be executed by a surety insurer admitted and duly authorized to

transact business in the State of California. If the Contract Price is increased by

Change Order, Contractor shall increase the Performance and/or Payment Bond

amount(s) if and to the extent required by the Engineer.

Notwithstanding the foregoing, for any Contract awarded for a Contract

Price of $25,000.00 or less, no Performance Bond or Payment Bond is required

unless specifically required in the Special Provisions, except as otherwise

required by any laws or regulations.

3-5 RETURN OF BID SECURITY

After bids have been received and reviewed, Bid Security will be returned

to the respective Bidders except those submitted by the three lowest responsible

Bidders. The Bid Security of the three lowest responsible Bidders will be returned

after the Contract is executed, subject to the provisions of Section 3-7 below.

3-6 EXECUTION OF CONTRACT

The Contract shall be executed by the successful Bidder and returned to

the City together with the Performance and Payment Bonds, not later than

fifteen (15) calendar days after the date the Contract is awarded.

3-7 FAILURE TO EXECUTE CONTRACT

Failure of the lowest responsible Bidder, the second lowest responsible

Bidder, or the third lowest responsible Bidder to execute a formally bid Contract

and file acceptable Bonds and insurance as provided in the Contract Documents

shall be just cause for the City Council to void the Contract award to that Bidder

and utilize that Bidder’s Bid Security to recover the City’s cost as provided

below.

If the lowest responsible bidder refuses or fails to execute the Contract

as required herein, the City Council may award the Contract to the second lowest

responsible Bidder. If this occurs, the amount of the lowest responsible Bidder’s

Bid Security shall be applied by the City to the difference between the lowest

Bid and the Bid of the second lowest responsible Bidder and the surplus, if any,

shall be returned to the lowest responsible Bidder if a check is used, or shall be

credited to the surety on the Bidder’s Bond if a Bond is used.

On refusal or failure of the second lowest responsible Bidder to execute

the Contract, the City Council may award the Contract to the third lowest

responsible Bidder. If this occurs, in addition to application of the lowest

Bidder’s Bid Security as provided above, the amount of the second lowest

responsible Bidder’s Bid Security shall be applied by the City to the difference

3-3

between the second lowest Bid and the Bid of the third lowest responsible

Bidder, and the surplus, if any, shall be returned to the second lowest responsible

Bidder if a check is used, or credited to the surety on the second lowest Bidder’s

Bond if a Bond is used.

The successful Bidder may file with the Engineer a written notice, signed

by the Bidder or its authorized representative, specifying that the Bidder will

refuse to execute the Contract if presented. The filing of such notice shall

immediately have the same force and effect as the failure or refusal of the

Bidder to execute the Contract and furnish acceptable Bonds within the time

prescribed above.

3-8 FORM OF AGREEMENT AND SURETY BONDS

The form of the Agreement and the form of the Payment and Performance

Bonds required to be executed by the successful Bidder shall be approved by the

City Attorney.

4-1

Section 4

SCOPE OF WORK

4-1 INTENT OF PLANS AND SPECIFICATIONS

The intent of the Plans and Specifications is to prescribe the details for

the completion of the Work that Contractor undertakes to perform in accordance

with the terms of the Contract. Where the Plans and Specifications describe

portions of the Work in general terms, but not in complete detail, it is understood

that only the best general practice is to prevail and that only materials and

workmanship of the best quality shall be used. Unless otherwise specified,

Contractor shall furnish all labor, materials, tools, equipment, and incidentals,

and do all the Work involved in executing the Contract in a satisfactory and

workmanlike manner.

4-2 CLEANING UP

Contractor shall not allow the site of the Work to become littered with

trash, debris, garbage or waste material, and shall maintain the site in a neat,

orderly, safe and healthful condition until completion and acceptance of the

Work. Before final inspection of the Work, Contractor shall clean the work site

and all ground occupied by Contractor in connection with the Work of all rubbish,

excess materials, falsework, temporary structures and equipment. All parts of

the Work shall be left in a neat and presentable condition. Contractor shall

implement a program of proper cleaning and “housekeeping” practices,

employee training and other measures as needed to consistently maintain a clean

Work site and shall at all times take all measures necessary to protect work in

place and materials and equipment stored on site from contamination by dust,

dirt, debris or mold. Full compensation for cleaning up and protection of work,

materials and equipment is included in the prices paid for the various Contract

items of work, and no separate or additional payment shall be made for cleaning

up and protection of work, materials and equipment.

4-3 LINES AND GRADES

All Work done under this Contract shall be done to the lines and grades

shown on the drawings. Contractor shall keep the Engineer informed, at least 2

working days in advance, of the times and places at which Contractor wishes to

do work, in order that lines and grades may be furnished and necessary

measurements for record and payment made with the minimum of inconvenience

to the Engineer and delay to Contractor.

4-2

The datum to which all elevations mentioned herein or shown on the

drawings refer is the official datum of the City of Sacramento, unless specifically

shown or stated to be otherwise.

4-4 CHANGES IN THE WORK

The City reserves the right to make such alterations, deviations, additions

to or deletions from the Work or any of the Contract Documents, including the

right to increase or decrease the quantity of any item or portion of the Work or

to eliminate any item or portion of the Work, as may be deemed necessary or

advisable by the Engineer, and to require such extra work as may be determined

by the Engineer to be necessary for the proper completion or construction of the

whole Work.

Any such changes shall be set forth in a Change Order that shall specify,

in addition to the work to be done or omitted in connection with the change

made, the adjustment of Contract time, if any, and the increase or decrease in

Contractor’s compensation, if any, for that work. A Change Order issued by the

Engineer shall not be deemed approved and effective until signed by Contractor

(or otherwise deemed approved by Contractor as provided in this Section) and

approved by the City in accordance with applicable approval requirements of the

Sacramento City Code. The City’s payment in accordance with the provisions for

compensation set forth in an approved Change Order shall constitute full

compensation for all work included in or required by the Change Order, including

all direct, indirect and consequential costs incurred or claimed by the

Contractor.

Contractor may contest the terms or conditions of a Change Order issued

by the Engineer by submitting a written protest to the Engineer within 15

calendar days after Contractor’s receipt of such Change Order. The protest shall

state the points of disagreement, the applicable Contract Document references,

and the quantities and costs involved. If a written protest is not submitted within

the 15 calendar day period; (1) payment shall be made as set forth in the Change

Order, and Contractor shall not be entitled to any additional compensation for

all work included therein or required thereby; and (2) the Change Order shall be

deemed to have been approved and executed by Contractor.

Upon receipt of an approved Change Order, Contractor shall proceed with

the ordered work. In those instances where the Work would be delayed by

waiting for City to issue and/or approve a Change Order, the Engineer may direct

work to be done by issuing a written Field Order, and Contractor shall proceed

with the work so ordered prior to actual receipt of an approved Change Order.

In those cases, the Engineer shall, as soon as practicable, issue a Change Order

for the ordered work.

4-3

Increases or decreases in the quantity of a unit price bid item of Work

shall be determined by comparing the total quantity of that item of Work with

the bid quantity. If the total quantity of a unit price bid item of Work is

increased, the Engineer shall determine in the Engineer’s sole discretion whether

to pay for the additional quantity of the item (i) at the Contract unit price for

the item, (ii) at a different unit price or in a lump sum, if such price or sum is

agreed to by Contractor, or (iii) by cost and percentage, as provided in Section

8-10 below. If the total quantity of any item of Work required under the Contract

is decreased, the Engineer shall determine the reduction in compensation for the

item based on the Contract unit price for the item; provided that if the

compensation for any “major item” (defined below) is reduced by more than 20%

of the cost bid for that item, the Engineer may agree to pay Contractor for lost

overhead resulting from such reduction, if any, as determined by the Engineer

in the Engineer’s sole discretion; provided, further, that if the Engineer

eliminates in its entirety an item of the Work, the reduction in compensation

therefore shall be determined in accordance with Section 4-5 below.

As used in this Section and Section 4-5, “major item” means an item of

the Work with a cost, computed on the basis of the bid quantity for the item,

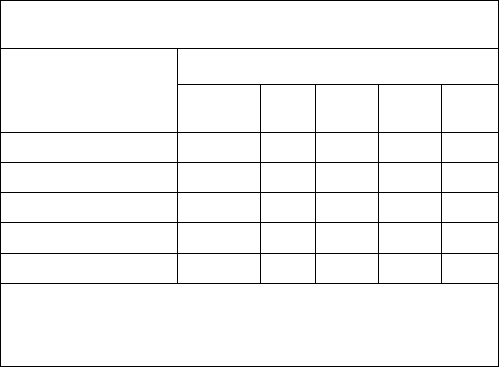

that exceeds the following percentages of the Contract price:

1. 10 % of the original Contract price, for Contracts originally awarded for a

price of less than one million dollars.

2. 8 % of the original Contract price, for Contracts originally awarded for a

price of at least one million dollars but less than five million dollars.

3. 6 % of the original Contract price, for Contracts originally awarded for a

price of at least five million dollars but less than ten million dollars.

4. 5 % of the original Contract price, for Contracts originally awarded for a

price of ten million dollars ($10,000,000.00) or more.

For extra work that does not constitute an increase of a unit price bid

item of the Work, the Engineer shall determine, in the Engineer’s sole discretion,

whether to pay for the extra work (i) at a unit price or lump sum agreed to by

Contractor, or (ii) by cost and percentage, as provided in Section 8-10.

4-5 ELIMINATED ITEMS

Notwithstanding any other provision of the Contract Documents, the

Engineer may at any time, in writing, entirely eliminate any item(s) of the Work

if the Engineer determines, in the Engineer’s sole discretion, that the item is

4-4

unnecessary to the project or will be performed by the City’s own personnel.

Any elimination of Work is not a waiver or invalidation of any of the conditions

or provisions of the Contract. If any item of Work is entirely eliminated,

Contractor shall not receive any compensation for the eliminated item, except

for actual costs incurred in connection with the eliminated Contract item if

reasonably incurred prior to the date of notification in writing by the Engineer

of the elimination. The payment by City for actual costs reasonably incurred by

Contractor, if any, prior to elimination of an item as provided in this Section

shall be computed in the same manner as if the work were to be paid by cost

and percentage as provided in Section 8-10 of these Specifications. In addition,

if any major item is entirely eliminated, the Engineer may agree, in the

Engineer’s sole discretion, to pay Contractor for lost overhead resulting from the

elimination.

If material acceptable to the City is ordered by Contractor for the

eliminated item prior to the date of notification of the elimination by the

Engineer, and if orders for that material cannot be canceled, the material shall

be paid for at the actual cost to Contractor. If so, the material paid for shall

become the property of the City. If the material is returnable to the vendor and

if the Engineer so directs, the material shall be returned and Contractor shall be

paid for the actual cost of charges made by the vendor for returning the material.

4-6 EXTRA WORK

Work is considered extra work only when the Engineer determines that

the work is not covered by any of the various items for which there is a bid price

or by combinations of those items. Contractor shall perform extra work and

furnish labor, material and equipment for extra work upon receipt of a Change

Order or other written order of the Engineer (including a Field Order) directing

Contractor to perform such extra work, in accordance with the provisions of

Section 4-4 above. Extra work must be authorized in writing by the Engineer

before the work is started. No payment shall be made for extra work performed

prior to Engineer’s prior written authorization.

4-7 GENERAL

The parties intend that differences between the City and Contractor,

arising under the Contract, be brought to the attention of the Engineer at the

earliest possible time in order that such matters may be settled, if possible, or

other appropriate action promptly taken. The City and Contractor agree to

initially strive to resolve all disputes amicably and in an informal manner. Any

dispute resolved informally shall be documented by the Engineer, and if the

dispute resolution involves a change in the Contract Work, increase or decrease

in the compensation due the Contractor, or adjustment in the time of completion

4-5

of the Work, then the informal dispute resolution shall be confirmed by a Change

Order pursuant to the Contract and Section 4-4 above. Informal discussions or

negotiations with the Engineer or other City representatives concerning informal

resolution of a dispute shall not suspend the claim filing and other deadlines

provided below, unless so provided by the Engineer in writing.

4-8 COMPLIANCE REQUIRED

Except as specifically otherwise provided in these Specifications,

Contractor shall not be entitled to payment of any additional compensation or

damages for any cause, including, but not limited to, any act or failure to act,

by the Engineer or the City, or any officer, employee, agent or contractor of the

City, the presence or discovery of any condition, or the happening of any event

or occurrence, unless Contractor gives the Engineer timely written notice of and

supporting data for any such potential claim and complies with the dispute

procedure as specified below. If the Contractor fails to timely file a written

Claim in accordance with Section 4-10 below, then the Contractor shall be

deemed to have waived any right or remedy to thereafter pursue the claim

against the City in any administrative, arbitration or litigation proceeding.

4-9 DEFINITION OF CLAIM

A “Claim” means a separate demand by the Contractor for: (a) a time

extension (including a demand for relief from damages or penalties for delay

assessed by the City under the Contract); (b) payment of money or damages

arising from work done by, or on behalf of, the Contractor pursuant to the

Contract and payment of which is not otherwise expressly provided for or the

Contractor is not otherwise entitled to; or (c) payment of an amount that is

disputed by the City.

The procedures and remedies set forth in sections 4.7-4.11 shall not apply

to: (i) any claim by the City against the Contractor or its surety or sureties (unless

the City, in its sole discretion, opts to proceed hereunder); (ii) any claim or

dispute relating to stop notices; or (iii) any claim relating to the approval, refusal

to approve or substitution of any subcontractor, regardless of tier, pursuant to

Public Contract Code section 4700, et seq.

4-10 REQUIREMENTS FOR FILING CONTRACT CLAIM; CONTENTS; FILING

DEADLINE

The Contractor may file a Claim with the Engineer. A Claim must: (a) be

in writing; (b) be labeled or clearly indicated as a Claim under the Contract; (c)

set forth in detail the reasons why the Contractor believes additional

compensation or a time extension is or may be due, the nature of the costs

involved, and, insofar as possible, the amount of the Claim; (d) include

documents that support and substantiate the Claim; and (e) include the following

4-6

certification, properly completed and executed by Contractor or any officer of

Contractor:

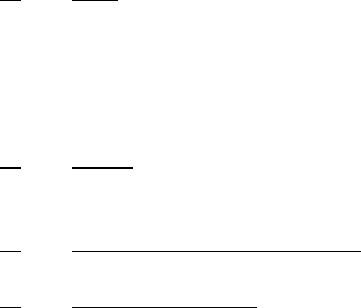

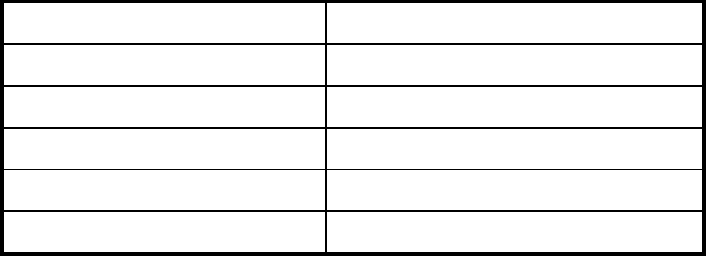

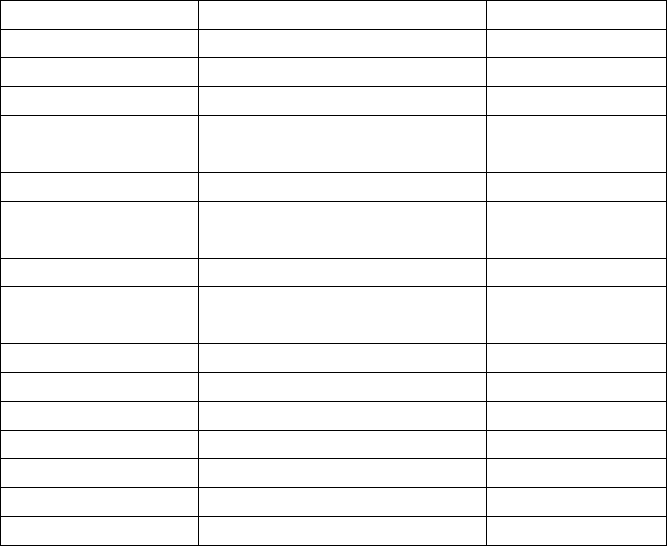

I, _______________________________BEING THE

______________________(must be an owner or officer)

OF____________________(CONTRACTOR), DECLARE UNDER PENALTY OF

PERJURY UNDER THE LAWS OF THE STATE OF CALIFORNIA, AND I DO PERSONALLY

CERTIFY AND ATTEST THAT: I HAVE THOROUGHLY REVIEWED THE ATTACHED

CLAIM FOR ADDITIONAL COMPENSATION AND/OR EXTENSION OF TIME, AND KNOW

ITS CONTENTS, AND THE CLAIM IS TRUTHFUL AND ACCURATE; THAT THE AMOUNT

AND/OR CONTRACT TIME EXTENSION REQUESTED ACCURATELY REFLECTS THE

CONTRACT ADJUSTMENT FOR WHICH THE OWNER IS LIABLE; AND FURTHER, THAT

I AM FAMILIAR WITH CALIFORNIA PENAL CODE SECTON 72 AND CALIFORNIA

GOVERNMENT CODE SECTION 12650, ET SEQ., PERTAINING TO FALSE CLAIMS, AND

FURTHER KNOW AND UNDERSTAND THAT SUBMISSION OR CERTIFICATION OF A

FALSE CLAIM MAY LEAD TO FINES, IMPRISONMENT, AND OTHER SEVERE LEGAL

CONSEQUENCES.

A Claim must be submitted to the Engineer within the following claim

filing deadlines: (a) if the Claim relates to extra, additional or unforeseen work

for which the Contractor intends to demand additional compensation, a time

extension, or both, notice shall be given to the Engineer prior to the time that

the Contractor commences performance of the work giving rise to the potential

claim for additional compensation or time extension, and Contractor shall not

proceed with that work until so directed by the Engineer in writing; and (b) for

all other Claims not included within (a) such as matters covered by the liquidated

damages provisions of the Contract or a Claim that is based directly and solely

on differences in measurements or errors in computation of Contract pay

quantities, the claim must be filed on or before 15 days after the date of the

occurrence, event or circumstance giving rise to the Claim. In no event shall a

Claim be filed later than the date of final payment.

Any additional data supporting the Claim must be given to the Engineer

not later than 30 days after the date of such written notice, unless the Engineer,

in writing, allows an additional period of time to ascertain more accurate data

supporting the claim. This data shall be accompanied by Contractor’s written

statement that the amount claimed covers all known amounts (direct, indirect,

and consequential) to which Contractor is entitled as a result of such condition,

act, failure to act, event, thing or occurrence.

4-11 ALL CLAIMS SUBJECT TO PUBLIC CONTRACT CODE SECTION 9204;

PROCEDURE

This procedure applies to the handling and resolution of all Claims sent to

the City, whether or not by registered mail or certified mail with return receipt

4-7

requested in accordance with Public Contract Code section 9204(c)(1). With

respect to all Claims submitted to the City in accordance with this procedure,

the provisions of Public Contract Code section 9204 shall apply. Pursuant to

Public Contract Code section 9204(f), the City has prescribed reasonable change

order, claim, and dispute resolution procedures and requirements in addition to

the provisions of section 9204 that do not conflict with or otherwise impair

section 9204’s timeframes and procedures.

1. Upon receipt of a properly submitted Claim, the Engineer shall conduct a

reasonable review of the Claim and, within a period of 45 calendar days,

provide the Contractor a written statement identifying what portion of

the claim is disputed and what portion is undisputed. Upon receipt of a

Claim, the Engineer and Contractor may, by mutual agreement, extend

the 45-calendar day time period.

2. The Contractor shall furnish reasonable documentation to support the

claim consistent with the requirements of Section 4.10.

3. If the Contractor disputes the Engineer’s written response, the Contractor

may request in writing an informal conference to meet and confer for

settlement of the issues in dispute. Such request by Contractor shall be

made within 15 calendar days from the date of the written statement

given by the Engineer. Upon receipt of a request in writing, the City shall

schedule a conference within 30 calendar days for settlement of the

dispute. The informal conference shall be conducted by the Division

Manager for the purpose of resolving the dispute.

4. Written notice of the date, time and location of the conference shall be

provided to Contractor not less than ten calendar days prior to the date

of the conference. On such date, or such other date to which the parties

may agree, Contractor shall be afforded a reasonable opportunity to

present Contractor’s position on and substantiation for the Claim. The

conference shall be conducted in an informal manner, and no record shall

be made of the proceedings, except that any written materials submitted

by the City or Contractor shall be preserved by the Division Manager until

the Work is finally accepted by the City.

5. Within ten days following the conclusion of the conference, if the Claim

or any portion of the Claim remains in dispute, the Division Manager shall

provide the Contractor a written decision identifying the portion of the

Claim that remains in dispute and the portion that is undisputed. Any

decision by the Division Manager to pay additional compensation to the

Contractor shall be contingent upon approval of a change order

authorizing such compensation by the Sacramento City Council, unless

City Council approval of the change order is not required under the

4-8

Sacramento City Code. Payment due on an undisputed portion of the claim

shall be processed and made within 60 calendar days after the Division

Manager issues the written decision.

6. If the Contractor disagrees with the Division Manager decision, the

Contractor shall, within 14 calendar days after the Contractor receives

the Division Manager’s decision, file a written request with the City to

submit the disputed portion of the claim to nonbinding mediation, with

the City and the Contractor sharing the associated costs equally.

Contractor hereby expressly waives all Claims not timely submitted to

mediation in accordance with this Section. The City and Contractor shall

mutually agree to a mediator or mediators within 10 days after the

disputed portion of the claim has been identified in writing. As part of the

process of evaluating a proposed mediator, each party may request that

the proposed mediator(s) disclose any prior or existing financial

relationship with either party. If the parties cannot agree upon a mediator

or mediators, each party shall select a mediator and those mediators shall

select a qualified neutral third party or parties to mediate with regard to

the disputed portion of the claim. Each party shall bear the fees and costs

charged by its respective mediator in connection with the selection of the

neutral mediator. If mediation is unsuccessful, the parts of the claim

remaining in dispute shall be subject to applicable procedures set out in

subsection 9 below.

7. The mediator, using advice and input from the parties, shall set the time

of each mediation session, as well as the mediation protocol (i.e.,

submission of briefs, statement of damages, etc.). The mediation will be

held at any convenient location agreeable to the mediator and the parties,

as the mediator determines. All reasonable efforts will be made by the

parties and the mediator to schedule the first session within 30 calendar

days after selection of the mediator.

8. The mediation may be terminated: (a) by the execution of a settlement

agreement by the parties; (b) by a written declaration of the mediator to

the effect that further efforts at mediation are no longer worthwhile; or

(c) by a writing on behalf of a party or parties to the effect that the

mediation proceedings are terminated.

9. If, at the termination of the mediation proceedings pursuant to Section

4.11.8, the Claim(s), or any portion thereof, remain(s) in dispute, the

City’s position shall constitute its final decision with regard to the

Claim(s). Any litigation arising out of the Claim(s) and the Contract

Documents shall be brought in the Sacramento County Superior Court, and

Contractor expressly waives the removal provisions of California Code of

Civil Procedure Section 394.

4-9

4-12 CONTRACT WORK PENDING CLAIM RESOLUTION

In the event of any dispute between the City and Contractor, or during

the pendency of any Claim(s) or associated proceedings under this Section or the

Contract Documents, Contractor shall not stop, or delay performance of, the

Work, but shall prosecute the Work diligently to completion in the manner

directed by the Engineer.

4-13 DISPUTES INVOLVING DESIGN PROFESSIONALS

If any Claim(s) asserted by the Contractor arise from or is/are related, in

any manner, to conduct or actions for which a design professional may be

responsible, the parties acknowledge and agree that the City may, in its sole

discretion, require the participation the design professional in any dispute

proceeding under this Section. This right shall remain solely within the discretion

of the City, and Contractor shall have no rights under the Contract Documents

to require or seek to compel the participation the design professional in any

dispute proceeding under this Section or elsewhere under the Contract

Documents.

4-14 ATTEMPT TO COMPROMISE AND SETTLE

All communications, statements, correspondence, information and other

evidence, whether documentary or oral, made or presented at, or in

anticipation of, the dispute resolution procedures set forth in sections 4.7-4.11

shall be deemed an attempt to compromise and settle the Contractor’s claim

under California Evidence Code section 1152, and as such will be inadmissible

for any reason in any litigation that may arise pertaining to the Claim or the

Contract.

5-1

Section 5

CONTROL OF WORK AND MATERIALS

5-1 AUTHORITY OF ENGINEER

As defined in Section 1 of these Specifications, “Engineer” may mean

either the Director or the representatives authorized by the Director to exercise

control and supervision of the Work. Much of the actual supervision and control

of the project may be by subordinate representatives designated as “Engineer.”

However, whenever in these Specifications, Plans or Special Provisions, the

Director is designated as the authority in any matter, it will mean only the

Director and not subordinates working under the Director’s supervision.

Whenever the word “Engineer” is used in these Specifications, Plans or Special

Provisions, then either the Director’s subordinates assigned to the supervision

and control of the Work or the Director will exercise such authority.

The Engineer will decide any and all questions as to the quality and

acceptability of materials furnished, work performed, and rate of progress of the

Work. The Engineer will decide all questions as to the interpretation of the

Specifications, Plans or Special Provisions, the fulfillment of the Contract on the

part of Contractor, and the rights of different contractors on the project. The

Engineer will determine the amount and quality of the Work performed and

materials furnished, for payment under the Contract.

Whenever, in these Specifications, or upon the Plans, the words

“directed,” “required,” “permitted,” “ordered,” “designated,” “prescribed,” or

words of like import are used, the direction, requirement, permission, order,

designation, or prescription of the Engineer is intended. Similarly, the words

“approved,” “acceptable,” “satisfactory,” or words of like import, mean

approved by, or acceptable to, or satisfactory to the Engineer, subject in each

case to the final determination of the Director or the City Council.

5-2 CONFORMITY WITH PLANS AND ALLOWABLE DEVIATIONS

Finished surfaces shall conform to the lines, grades, cross-sections, and

dimensions shown on the approved Plans and working drawings, unless a

deviation from the Plans is authorized in writing by the Engineer.

5-3 COORDINATION OF CONTRACT DOCUMENTS

These Specifications, the Plans, Special Provisions, and all supplementary

Plans, drawings, and other Contract Documents are essential parts of the

Contract, and a requirement occurring in one is just as binding as though

occurring in all. These documents are intended to be integrated to describe and

5-2

provide for a complete Work. Whenever a reference is made in these

Specifications to a Section or subsection of another agency’s Specifications, such

reference shall be deemed to include the General Provisions of such other

Specifications of which the Section or subsection is a part, to the extent

pertinent to the reference and not inconsistent with the other Contract

Documents. In the event of a conflict in the Contract Documents, unless

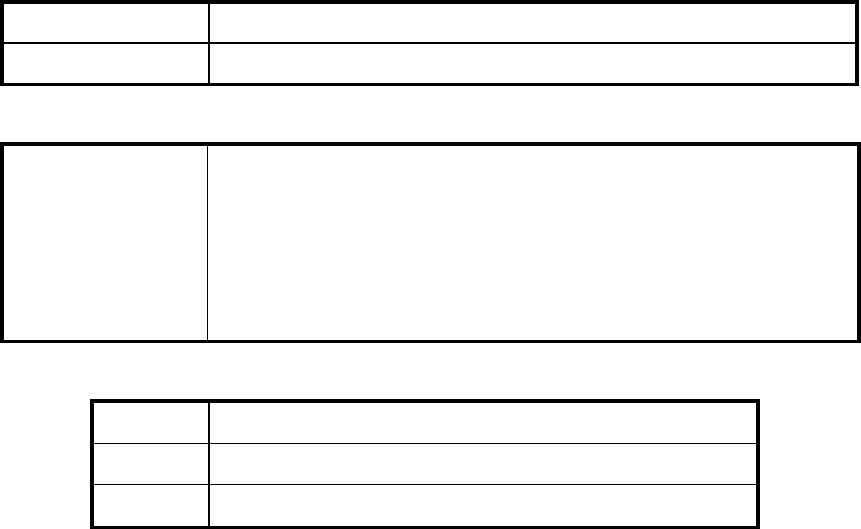

expressly indicated otherwise, the governing priorities are as follows:

1. A Change Order.

2. The Agreement.

3. Addenda. Subsequent addenda shall govern over prior addenda only to

the extent specified.

4. In case of conflict between the Specifications and the Special Provisions,

the Special Provisions shall govern.

5. In case of conflict between Plans and Specifications, the Plans shall govern

in matters of quantity and the Specifications shall govern in matters of

quality.

6. In case of conflict within the Plans involving quantities and quality,

Contractor shall furnish the greater quantity and quality material and

procedure.

7. In case of conflict within a plan sheet involving figured or numerical

dimensions the profile shall govern over the layout.

8. In case of conflict within the Specifications involving quality of material

or procedure, Contractor shall furnish the higher quality material and

procedure.

9. Specific notes shall govern over other notes and other portions of the Plans

except Schedules.

10. Larger scale drawings shall govern over smaller scale drawings.

11. Detail plans shall govern over standard plates bound within the

Specifications.

12. Figured or numerical dimensions shall govern over dimensions obtained by

scaling.

13. Where provisions of codes, safety orders, Contract Documents, referenced

manufacturers’ specifications or industry standards are in conflict, the

more restrictive and higher quality shall govern.

Contractor shall not take advantage of any error, discrepancy or omission

in any of the Contract Documents if such error, discrepancy or omission was or

should have been apparent to Contractor. As soon as Contractor discovers any

apparent error, discrepancy or omission, Contractor shall immediately notify the

Engineer, so that the Engineer may make a determination on the matter, which

determination shall be final, subject to Contractor’s right to submit a claim in

accordance with applicable provisions of the Contract Documents.

5-3

The Work shall be performed and completed according to the meaning

and intent of the Contract Documents.

In addition to the drawings made a part of this Contract at time of signing,

by incorporation or reference, the Engineer may furnish such additional drawings

from time to time during the progress of the Work, as are necessary to make

clear and to define in greater detail, as may be necessary, the intent of the

Specifications, Plans, Special Provisions and other Contract Documents and

Contractor shall make its Work conform to all such drawings.

Should it appear that the Work to be done or any of the matters related

to the Work are not sufficiently detailed or explained in the Contract Documents,

Contractor shall provide the Engineer with a request for information (RFI)

requesting such information or explanations as may be necessary to complete

the Work. The City shall respond to RFIs within 20 calendar days of receipt,

unless the Engineer reasonably determines that a longer time period is necessary

to provide the information requested by Contractor. The City response (but not

Contractor’s RFI) shall become part of the Contract, and Contractor shall be

responsible for conforming its activities and operations, including the activities

and operations of all subcontractors and suppliers, to all applicable

requirements, terms and conditions of the City’s response.

5-4 COOPERATION OF CONTRACTOR

After all necessary signatures by City, City will supply Contractor a copy

of the Plans, Special Provisions, and the fully executed Agreement. City will also

make available to Contractor at least five (5) copies of the Plans and Special

Provisions for Contractor’s use in prosecuting the Work. If Contractor requests

additional copies of the Plans or Special Provisions, the City or its designated

reprographics firm will supply such additional copies at Contractor’s expense.

Contractor shall give the Work the constant attention necessary to

facilitate the satisfactory progress of the Work. Contractor shall cooperate with

the Engineer, inspectors and with other contractors in every way possible.

Contractor shall at all times have a competent Superintendent at the site of the

Work. Contractor’s Superintendent shall be fully authorized as Contractor’s

agent on the Work. The Superintendent shall be capable of reading and

understanding all of the Contract Documents. Unless otherwise approved by the

Engineer, the Superintendent shall be an employee of Contractor responsible for

providing continuous on-site supervision of the Work and shall be fully authorized

to receive and follow any instruction given by the Engineer and to sign Change

Orders on behalf of Contractor. Unless specifically called for by the Special

Provisions, Contractor is not required to provide an office for use by the

Engineer.

5-4

If requested by the Engineer, Contractor shall provide daily reports signed

by Contractor’s Superintendent indicating the location and description of

operations and details of the equipment and labor used to perform the items of

Work. Such details shall include the description of the items of Work, names and

classifications of laborers, hours worked, description of equipment used,

equipment numbers, and hours equipment are in use, and hours equipment may

be idle.

5-5 CONSTRUCTION STAKES

The Engineer will furnish Contractor with all lines, grades and

measurements necessary for the proper prosecution and control of the Work

unless stated otherwise in the Special Provisions. Contractor shall provide the

Engineer with the City’s standard Survey Request Form at least three (3) working

days before construction stakes are required. The Engineer may reject any

unreasonable or incomplete Survey Request Form and require Contractor to

resubmit. Contractor shall have no claim for any costs, damages or extensions of

time arising from any delay caused by Contractor’s submittal of an unreasonable

or incomplete Survey Request Form.

Such stakes and markings as the Engineer may set for either the City’s or

Contractor’s guidance shall be preserved by Contractor. In the event that the

stakes or marks placed by the Engineer are destroyed through carelessness or

negligence on the part of Contractor or any Subcontractor and the destruction

of these stakes or marks causes a delay in the Work, Contractor shall have no

claim for damages or extensions of time. Additionally, the City reserves the right

to charge Contractor or deduct from the progress payments the costs to the City

for any re-staking or remarking required as a result of carelessness or negligence

on the part of Contractor or any Subcontractor.

5-6 PERMANENT SURVEY MONUMENTS

Contractor is responsible for verifying that the arrangements have been

made for preserving and perpetuating all permanent survey monuments that will

be affected by the Work. Contractor is responsible for preserving all permanent

survey monuments that are not proposed to be disturbed. Contractor shall

provide a minimum of ten (10) working day notice to Engineer prior to

disturbance or removal of any permanent survey monument, and shall coordinate

with the Engineer to reset monuments or provide permanent witness monuments

and file the required documentation with the County Surveyor pursuant to

Business and Professions Code Section 8771.

5-5

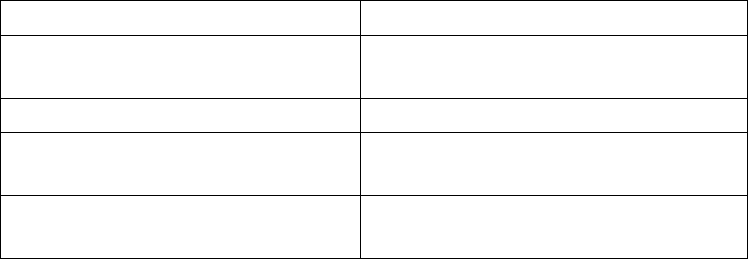

5-7 SUBMITTALS

Contractor shall supply all submittals required by the Special Provisions or

the Engineer. Unless otherwise specified herein, Contractor shall deliver five (5)

copies of the submittals to the Engineer when required by the Contract

Documents or the Engineer. Within twenty (20) calendar days after receipt of a

submittal, the Engineer will return two (2) marked copies of the submittal to

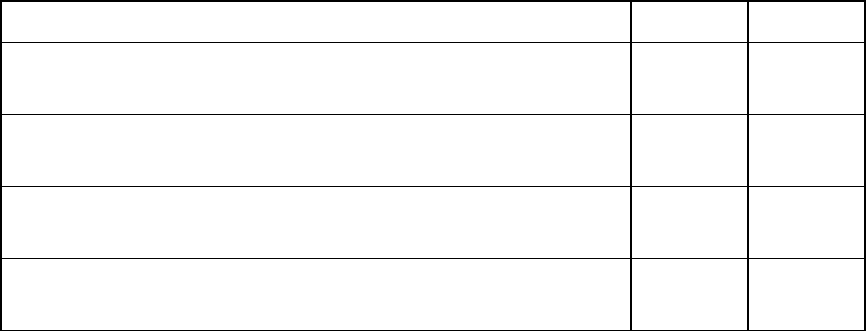

Contractor indicating one of the following four (4) actions taken by the Engineer,

in the Engineer’s sole discretion:

1. If the Engineer’s review indicates no exceptions, copies will be returned

marked "NO EXCEPTIONS TAKEN." Contractor may immediately

incorporate the material and equipment covered by the submittal into the

Work.

2. If the Engineer’s review indicates limited corrections are required, copies

will be returned marked "MAKE CORRECTIONS NOTED." Contractor may

immediately incorporate into the Work the material and equipment

covered by the corrected submittal, with the corrections noted by the

Engineer.

3. If the Engineer’s review indicates insufficient or incorrect data has been

submitted, copies will be returned marked "REVISE AND RESUBMIT." No

work may begin on incorporating the material and equipment covered by

this submittal into the Work until the submittal is revised, resubmitted,

and returned marked either "NO EXCEPTIONS TAKEN" or "MAKE

CORRECTIONS NOTED."

4. If the Engineer’s review indicates the material and equipment submittal

is unacceptable, copies will be returned marked "RESUBMIT." No work

may begin on incorporating the material and equipment covered by this

submittal into the Work until a new submittal is submitted and returned

marked either "NO EXCEPTIONS TAKEN" or "MAKE CORRECTIONS NOTED."

After approval by the Engineer, submittals (including any corrections

noted by the Engineer) shall become a part of the Contract, and the work shall

be done in conformity with such approved submittals. No work shall be started

or material or equipment purchased until the submittals have been approved.

Submittals furnished to the Engineer shall include finished drawings, if required,

that are neat, legible, to scale, and drawn to as large scale as reasonably

possible.

5-6

5-8 RECORD DRAWINGS

Contractor shall maintain a neatly and accurately marked set of record

drawings showing the final locations and layout of all facilities as-built. Drawings

shall be kept current weekly, with all work instructions and Change Orders,

accommodations, and construction adjustments. Drawings are subject to the

inspection by the Engineer at all times, and progress payments, or portions of

progress payments, may be withheld if drawings are not accurate and current.

Prior to City’s acceptance of the Work, Contractor shall deliver to the Engineer

one (1) set of neatly marked record drawings, accurately showing all the

information required above. If the Engineer does not approve the record

drawings, Contractor shall revise and resubmit the record drawings as necessary

to obtain the Engineer’s approval. If Contractor fails to comply with the

requirements of this section, the City may deduct and retain the cost of

preparing the record drawings from the Contract.

5-9 SUGGESTIONS TO CONTRACTOR ADOPTED AT CONTRACTOR’S OWN RISK

Contractor is solely responsible for determining whether to follow or

utilize any plan or method of work suggested by the Engineer to Contractor in

whole or in part, and Contractor shall assume all risks for this determination.

The Engineer and City will assume no responsibility or risk.

5-10 REQUEST FOR MODIFICATION OF WORK

Should conditions occur during the progress of the Work that make it

impossible for Contractor to comply strictly with the terms of the Contract with

respect to a portion of the Work, Contractor shall make written request to the

Engineer for a modification of such portion of the Work, provided that any

modification is not detrimental to the Work or create any additional cost to the

City. If the modification is acceptable to the Engineer, Contractor will be notified