Employer’s Guide to the

Hazard Communication Rule

Division of Occupational Safety and Health

www.Lni.wa.gov/Safety 1-800-423-7233

1

What is the Hazard Communication rule?

The Hazard Communication rule requires you

—

the employer

—

to inform and train your employees about hazardous chemicals in

your workplace.

Note: Washington State’s new Hazard Communication rule,

WAC 296-901-140, became effective April 15, 2013. It replaces the

Employer Hazard Communication rule, WAC 296-800-170.

The changes are based on the International Globally Harmonized

System of Classication and Labeling of Chemicals (GHS) and are

intended to improve comprehension of hazard information found

on product labels. For more information about GHS and Hazard

Communication, visit www.Lni.wa.gov/Safety/Topics/AtoZ/GHS .

The major changes include:

Hazard Classication providing specic criteria for classication of

health and physical hazards, as well as classication of mixtures.

More standardized labels that feature:

-

Hazard pictograms

-

A signal word, such as “Danger”

-

Hazard statement for each hazard class and category, including

precautionary statements

-

A product identier and a supplier identier

Safety Data Sheets (SDSs) that follow a standardized 16-section

format to replace Material Safety Data Sheets (MSDSs.)

Although content details on labels and SDSs are affected by the GHS,

many of the current requirements are not changing. For example,

requirements to distribute SDSs, label workplace containers and train

employees remain the same.

Employers must comply with changes to the rule according to the

following schedule:

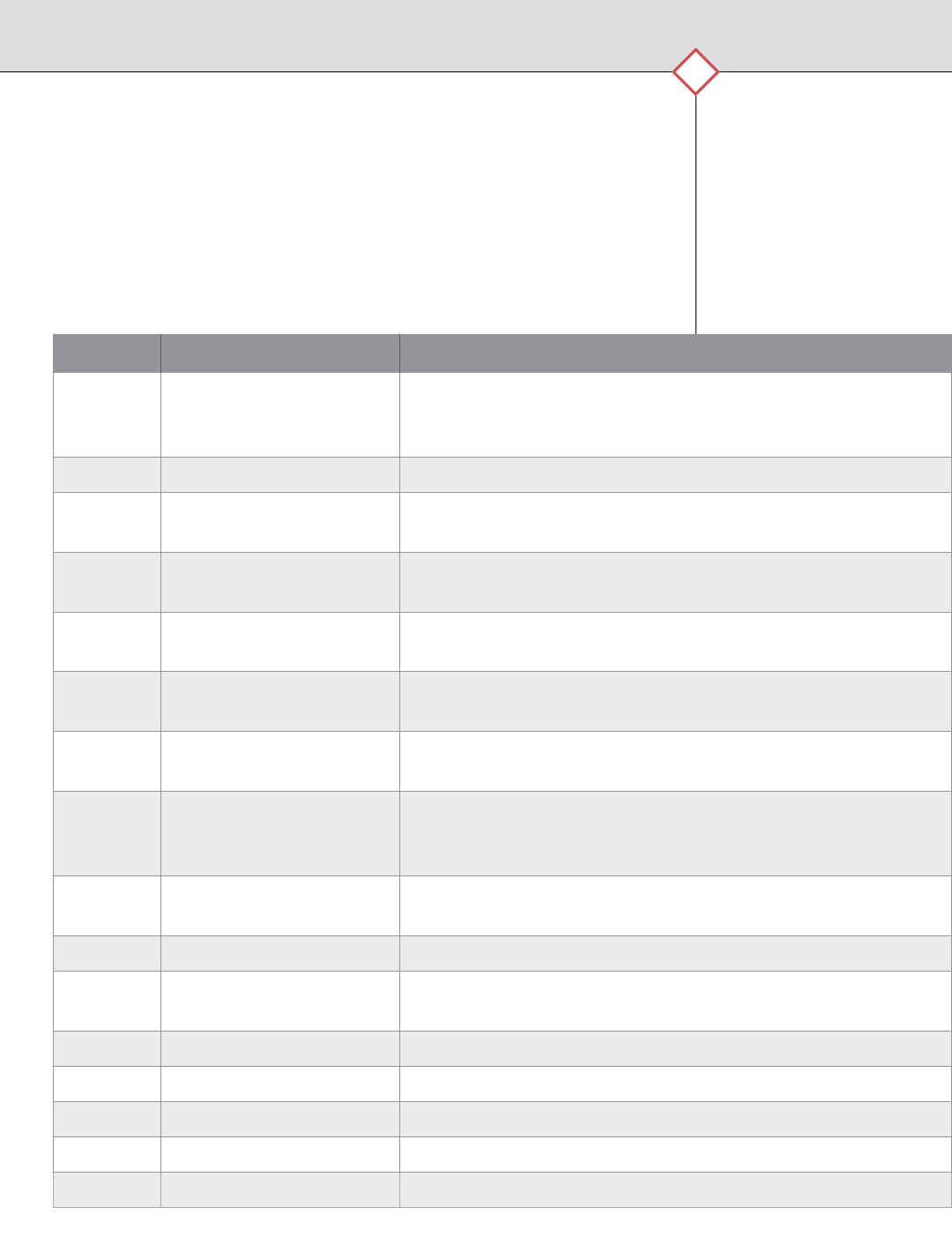

Who What By Date

Employers Train employees on the SDS (Safety Data Sheet)

format and new label elements.

June 1, 2014

Chemical

Manufacturers

and Importers

Comply with new SDS and label requirements. June 1, 2015

Distributors Not to ship unless container has GHS (Global

Harmonization System) label.

Dec. 1, 2015

Introduction

2

Who What By Date

Employers Update labels on “workplace” containers and train

employees on newly identified hazards. Update the

hazard communication program as needed.

June 1, 2016

All Until the dates listed in this table, you may comply

with either the:

-

New requirements in WAC 296-901-140, and/or

-

Current Hazard Communication rules

(WAC 296-800-170).

June 1, 2016

Which state agency administers this rule?

The Washington State Department of Labor & Industries (L&I)

administers this rule and other occupational safety and health rules

through its Division of Occupational Safety and Health (DOSH).

The Hazard Communication rule is part of the Washington

Administrative Code, WAC 296-901-140.

Do I need to read the Hazard Communication rule?

Yes! This booklet alone will not explain all of the requirements of the

Hazard Communication rule. You can easily access the rule on the L&I

website: www.Lni.wa.gov/Safety/Rules/Chapter/901 . Visit the Hazard

Communication topic page at www.Lni.wa.gov/Safety/Topics/AtoZ/GHS

for additional resources, such as:

A sample written program for chemical hazard communication

Sample forms

Training materials

Safety videos

If you have one or more employees who handle or are exposed to

chemicals at your workplace, you must comply with this rule to meet

your obligations as an employer. Failure to do so could lead to safety

and health citations and penalties.

How will this booklet help me?

This booklet describes the requirements of a hazard communication

program. It provides:

A checklist you can use to make certain you meet all of the

requirements of the Hazard Communication rule.

Questions and answers about employer requirements, including

information specic to agriculture.

Information on starting your employee training program.

This information goes beyond what is contained in the Hazard

Communication rule.

3

Checklist of Requirements

In addition to reading the Hazard Communication rule, ask yourself the

following questions to determine if your business has met all the safety

and health requirements for the rule:

■

Have we prepared a list of all

the hazardous chemicals in the

workplace?

■

Do we update our hazardous chemical

list regularly?

■

Have we obtained or developed a

Safety Data Sheet (SDS) for each

hazardous chemical we use?

■

Do we have a system to ensure that

we check all incoming hazardous

chemicals for proper labels and SDSs?

■

Do we have procedures to ensure

proper labeling or warning signs

for containers that hold hazardous

chemicals?

■

Are employees aware of the

specific information and training

requirements of our hazard

communication program?

■

Are employees familiar with the

different types of chemicals and the

hazards associated with them?

■

Have employees been informed of

the hazards associated with

performing non-routine tasks?

■

Do employees understand how

to detect the presence or release

of hazardous chemicals in the

workplace?

■

Are employees trained about

proper work practices and personal

protective equipment in relation to

the hazardous chemicals in their

work areas?

■

Does our training program provide

information on appropriate first aid,

emergency procedures and the likely

symptoms of overexposure?

■

Does our training program include an

explanation of labels and warnings

that are used in each work area?

■

Does our training describe where to

obtain SDSs and how employees may

use them?

■

Do we have a system to ensure that

we train new employees before

beginning work?

■

Have we developed a system to

identify new hazardous chemicals

before we introduce them into a

work area?

■

Do we have a system for informing

employees when we learn of new

hazards associated with a chemical

we use?

■

Do we have a records retention

system that will retain the SDSs or

the alternative record for a minimum

of 30 years?

4

Topic

Safety Data Sheets (SDSs)

Labels and Record Keeping

Training Your Employees

General Provisions of the Rule

How the Rule Applies to Different Chemicals or Products

Hazard Communication in Agriculture

The Role of the Department of Labor & Industries

Hazardous Chemicals in Communities

4

6

8

9

10

11

11

12

Safety Data Sheets (SDSs)

1. If I buy a hazardous chemical from a retail outlet (such as rust remover

from a hardware store or fertilizer from a nursery), who will provide

the SDS?

Retail distributors are required to provide SDSs to only those

customers with commercial accounts who make requests. The

retailer must post a sign informing employers that an SDS is

available. If you do not have a commercial account, you are

responsible for requesting an SDS from the manufacturer, importer

or wholesale distributor.

Wholesale distributors selling hazardous chemicals to employers

over the counter may also provide SDSs upon the request of the

employer at the time of the over-the-counter purchase, and they

must also post a sign or otherwise inform such employers that an

SDS is available.

If you do not have a commercial account and you purchase a

hazardous chemical from a retail distributor not required to

have an SDS on le (such as if the retail distributor does not have

commercial accounts and does not use the materials), the retail

distributor must provide you, upon request, with the name, address

and telephone number of the chemical manufacturer, importer or

distributor so that you can get an SDS.

Questions and Answers about the

Hazard Communication Rule

5

2. Are farm-chemical distributors required to provide SDSs?

Yes. All manufacturers, importers and distributors must provide

SDSs to employers who purchase hazardous chemicals. This

includes pesticide dealers. Pesticide applicators that sell pesticides

are considered distributors for the purposes of the rule.

3. What should I do if I get an SDS with blank spaces on it?

Contact the manufacturer or importer for a complete SDS. The

person who prepares the SDS must ll out the form completely

All elements of an SDS are now required; if no relevant

information is found for any subheading within a section on the

SDS, it must be marked to indicate that no applicable information

was found.

4. Who is responsible for the accuracy of SDSs?

The manufacturer, importer or employer preparing the SDS must

make certain the information accurately reects the scientic

evidence used in making the hazard determination.

5. Can SDSs be kept and made available electronically as long as employees

have proper access and knowledge of how to use them?

Yes. The rule says that an SDS may be in any form as long as it

contains the required information. You must make certain the

required information is provided for each hazardous chemical

and is readily accessible to employees in each work area on

each shift.

6. How often do SDSs need to be updated?

Each SDS must be updated within three months of the time the

manufacturer, importer or employer learns of any signicant new

information pertaining to the hazards of the chemical or ways to

protect against the hazards.

7. Do I have to obtain SDSs on hazardous chemicals we don’t use very often?

Yes. You must keep an SDS on each hazardous chemical used in

your workplace.

8. Do contractors have to make SDSs available to their employees when they

are working at non-fixed locations, such as construction sites?

Yes. SDSs may be kept at the contractor’s permanent base if

employees leave and return from that location on a daily basis.

Contractors who establish a temporary base, such as a trailer at a

work site, are required to have SDSs available at the site.

6

9. Must SDSs be translated into a foreign language if the majority of workers

don’t speak English?

No. However, a reasonable effort must be made to inform all

employees of the hazards in the workplace. L&I will, upon request,

provide assistance with translations for the following languages:

Cambodian, Chinese, Korean, Spanish and Vietnamese.

10. Will L&I approve all SDSs?

No. L&I does not approve the content of SDSs but will review them

on a spot-check basis for completeness and accuracy.

11. How are laboratories covered under the rule?

Laboratories, including school and college labs, have limited

coverage under the rule as described in WAC 296-901-14004. They

must follow the “Hazardous Chemicals in Labs” rule, WAC 296-828,

if it applies.

12. Are laboratories required to obtain SDSs for all hazardous chemicals, even

those that are old or infrequently used?

No. Laboratories are only required to keep SDSs that are received

for hazardous chemicals. These SDSs must be available to laboratory

personnel at all times. L&I recommends that laboratories obtain as

many SDSs as possible to help in developing their training programs.

13. Are schools and colleges required to tell students about the hazards of

chemicals they handle or are exposed to?

Teaching assistants, laboratory assistants and students employed

by schools are covered under the Hazard Communication rule and

must receive information and training.

14. If I don’t get an SDS with a product, can I assume it’s not hazardous?

No. You should call or write the manufacturer and ask for an SDS if

you suspect a chemical may be hazardous.

Labels and Record Keeping

15. What does the rule require for labeling?

The Hazard Communication rule requires that all workplace

containers of hazardous chemicals, including pesticides, be labeled,

tagged or marked with at least the following information:

a. Product identier

b. Signal word

c. Hazard statement(s)

7

d. Pictogram(s)

e. Precautionary statement(s) (applies only to shipping activities)

f. Name, address, and telephone number of the manufacturer, importer

or other responsible party (applies only to shipping activities).

Pesticide container labels regulated by EPA satisfy this requirement.

However, the Hazard Communication rule says that pesticides cannot

be put into unmarked containers and left unattended. Powered-air

spray tanks, hand-carried tanks or backpack tanks do not need to be

labeled when – and only when – the employee using the container

personally transferred the chemical from a labeled container and the

solution will be used immediately by the same employee.

16. Do all containers need to be labeled?

No. Portable containers that meet the “immediate use” criteria of

the rule do not have to be labeled.

17. Must labels be translated into a foreign language if the majority of workers

don’t speak English?

No. However, a reasonable effort must be made to inform all

employees of the hazards in the workplace. L&I will, upon request,

provide assistance with translations for the following languages:

Cambodian, Chinese, Korean, Spanish and Vietnamese. Written

request for translations may be sent to:

Department of Labor & Industries

Right-To -K now Program

P.O. Box 44610

Olympia WA 98504-4610

18. Do pipes and piping systems containing chemicals need to be labeled?

No. The rule requires only containers to be labeled. Pipes and

piping systems are not considered containers for the purpose of

hazard communication. (Other regulations may require pipes

and piping systems to be identied.) However, you must have a

method of informing your employees of the hazards of non-routine

tasks (for example, the cleaning of reactor vessels) and the hazards

associated with chemicals contained in unlabeled pipes in their

work areas.

19. Does a list of SDSs satisfy the requirement of a hazardous chemical

inventory?

Yes, as long as the product names or chemical names used on the

inventory are the same as those used on the SDSs and labels. A

copy of the list must be made available to employees.

8

Training Your Employees

20. If there is more than one employer at a single job site, who is responsible

for employee training?

Each employer must train his or her own employees. However,

if an employer hires employees on contract from a temporary

employment service, the hiring employer is responsible for

informing and training the temporary worker(s) about hazardous

chemicals at the work site.

21. Will employees who rarely encounter hazardous chemicals need to be trained?

Yes. Employees must be trained on any hazardous chemical to

which they could be exposed. Training should address the type of

exposure possible and the degree of hazard involved.

22. Do I have to train employees about handling each brand of chemical?

No. Different brands of the same chemical have the same hazard.

Information and training about one brand is considered to apply to

the other brands.

23. Do workers have to be retrained whenever a new brand is introduced into

the work area?

No. However, workers must be retrained whenever a new chemical

hazard is introduced.

24. Does a packaged instructional program satisfy the requirements for

training under the Hazard Communication rule?

No. General instructional programs can help to train your

employees, but they will not completely satisfy the training

requirements. You also need to create a written training program

and provide training on the specic hazardous chemicals used in

your workplace.

25. Is generic training acceptable if we use large numbers of chemicals?

Yes. The rule does not specify how training is to be performed. It

only species who will be trained and the minimum content of

the training. Grouping chemicals with similar hazards for training

purposes is acceptable.

26. Do I have to keep records about who has received training on hazardous

chemicals?

No. The rule does not require documentation of employee

training, but L&I recommends that you keep records to verify your

compliance with the employee training requirements.

9

General Provisions of the Rule

27. Does a complete list of hazardous substances exist?

No. However, there are several sources that list hazardous substances

or criteria for determining whether chemicals are hazardous. These

include the general occupational health standards (Chapter 296-62

WAC); Pre-GHS, Employer Chemical Hazard Communication

(WAC 296-800-170); Permissible exposure limits (PELs)

—

Airborne

Contaminants (WAC 296-841-20025); OSHA Guidance for Hazard

Determination (www.OSHA.gov/dsg/hazcom/ghd053107.html ); and

the latest edition of the ACGIH Threshold Limit Values Handbook,

available online at www.acgih.org .

28. Can I conduct my own hazard evaluation of a chemical?

Yes. If you choose not to rely on the manufacturer’s or importer’s hazard

evaluation, you have the right to evaluate a chemical yourself. You must

follow the requirements for hazard determination as dened in the rule.

You will be responsible for the completeness and accuracy of the

data sheet.

29. If my company is small, or I use only one or two hazardous chemicals, must

I still comply with the rule?

Yes, if you have employees, you must comply with the Hazard

Communication rule no matter how small your company or how

few hazardous chemicals you use.

30. Who is considered to be a chemical importer?

An importer is considered to be the rst business within the

customs territory of the United States that receives hazardous

chemicals produced in other states or countries. Importers who are

employers must also comply with the applicable sections of the rule.

31. Does the rule apply to refuse collectors and landfill operators?

Hazardous chemicals purchased for use by refuse collectors are

covered under this rule, but materials received for disposal are not.

Workers are protected from the hazards of disposal through the

accident prevention program required under WAC-296-800-140.

32. Are contractors required to notify employers about hazardous chemicals

on a job site?

Yes. Just as employers have the obligation to notify contractors

about hazardous chemicals at the work site, contractors are required

to provide SDSs at a central location for each hazardous chemical

to which the employees may be exposed. They are also required to

10

inform the employer of any precautionary measures necessary as a

result of hazardous chemicals they use, and provide an explanation

of the labeling system used for their hazardous chemicals.

How the Rule Applies to Different Chemicals

or Products

33. Are off-the-shelf products covered under this rule?

Yes. Consumer products are considered to be hazardous if there are

hazard warnings on the label that indicate a potential for physical

or health hazards.

34. Are radioactive chemicals covered under this rule?

Yes. Since the purpose of the Hazard Communication rule is

to protect employees from hazardous chemicals, radioactive

chemicals are covered. Other radioactive materials, such as those

used in medical treatment, are regulated by the Washington State

Department of Health under WAC 246-220 through 254.

35. How are pharmaceuticals covered by the rule?

The rule covers pharmaceutical drugs such as antineoplastic

(chemotherapy) agents, drugs that may cause eye or skin irritation,

and drugs that have carcinogenic potential or known toxic effects

when employees handle them.

Note: L&I adopted a Hazardous Drugs rule on Jan. 3, 2012,

with implementation beginning Jan. 1, 2015. See the Hazardous

Drugs topic page at www.Lni.wa.gov/Safety/Topics/AtoZ/

HazardousDrugs for more information.

36. Are wood products exempt from labeling and SDS requirements?

Wood and wood products are exempt, but wood dust and chemical

preservatives are covered and must be treated accordingly. In

addition, if sawing, sanding or other processing releases wood dust

into the air, the wood product is covered.

37. Are bricks and cinder blocks exempt from this rule?

Bricks and cinder blocks are exempt from the rule unless they are

cut or drilled. Cutting or drilling bricks or cinder blocks releases

silica dust into the air and silica is a serious health hazard. For more

information about silica, see WAC 296-841 Airborne Contaminants

at www.Lni.wa.gov/Safety/Rules/Chapter/841 . Permissible

Exposure Limits (PELs) for Airborne Contaminants can be found in

WAC 296-841-20025 Table 3.

11

38. Are biological agents covered under this rule?

No. Biological agents such as microorganisms are not included in

the denition of a chemical.

Hazard Communication in Agriculture

39. Does the Hazard Communication rule cover all agricultural employees

including seasonal and temporary employees?

Yes. All agricultural employees who handle or are potentially exposed

to hazardous chemicals must be included in the employer’s hazard

communication program. This includes pesticides and pesticide use.

40. Are agricultural employers exempt from the requirements to develop a

written hazard communication program?

No. All agricultural employers must develop a written hazard

communication program if their employees can be exposed, under

normal conditions of use or in a foreseeable emergency, to any

hazardous chemical including a pesticide.

41. As an agricultural employer, do I have to obtain SDSs for pesticides in

addition to the pesticide label?

Yes. SDSs must be obtained for all hazardous chemicals, including

pesticides that employees may encounter in their work activities.

42. Can agricultural employers who use pesticides combine elements of their

employee training and written hazard communication program with similar

training or written materials that may be required under other federal or

state pesticide regulations?

Yes. The intent of the rule is not to require duplicative programs if

requirements overlap with elements of other regulations. However,

the hazard communication program must include all chemicals and

not be limited to pesticides.

The Role of the Department of Labor & Industries

43. What will L&I do about manufacturers or importers located outside

Washington who do not provide SDSs?

L&I will take administrative and legal action, if necessary, to get

SDSs from uncooperative manufacturers, importers or distributors.

Federal OSHA will also assist in obtaining SDSs.

44. Will L&I evaluate the validity of trade secret claims?

Yes, however, L&I will use discretion in selecting specic claims

for evaluation.

12

Hazardous Chemicals in Communities

45. Whom do I contact about hazardous chemicals in my community?

The Washington State Department of Ecology administers the

Community Right to Know Act and other hazardous-waste

disposal laws. For information about hazardous chemicals in your

community, visit www.ecy.wa.gov/epcra .

13

Starting Your

Employee Training Program

The Hazard Communication rule requires you to develop and maintain

a written training program for both new and experienced employees and

to give all your employees information about the program.

Employees who are directly or potentially exposed to hazardous

chemicals on the job must receive additional information on the

particular hazards of the chemicals to which they are exposed or

potentially exposed. They also must be trained. You also must provide

training when a new chemical hazard is brought into the workplace.

Hazard communication training information and materials are available

at www.Lni.wa.gov/Safety/Topics/AtoZ/GHS . You will need to add

information specic to your workplace to meet the training requirements.

Step 1: Know the requirements

Read the employee training requirements of the Hazard

Communication rule

—

WAC 296-901-14016.

Step 2: Identify employees who must be trained

Determine which employees are exposed or potentially exposed to

hazardous chemicals in your workplace. These employees require

training beyond the information provided to all employees. (See the

sidebar on Page 15, How to Determine Your Employees’ Exposure

to Chemicals.)

Step 3: Inform all employees

Develop a program to inform all employees about:

The requirements of the Hazard Communication rule.

Any operations in their work areas that involve hazardous chemicals.

The location and availability of the written hazard communication

program, including the list(s) of hazardous chemicals and SDSs.

Step 4: Train employees who may have actual or potential exposure

The information and training your employees receive must be tailored

to the types of hazards and exposures they encounter. This training

must cover:

Details of the hazard communication program. The program and

training should explain the labeling system and SDSs, and include

instructions on how to obtain and use hazard information.

The location of your written hazard communication program, lists

of hazardous chemicals and data sheets.

14

How these employees can detect the presence or release of

hazardous chemicals.

Physical and health hazards of hazardous chemicals in the work

area, information about rst aid, emergency procedures and the

likely symptoms of overexposure.

How employees can protect themselves through exposure

control methods, including work practices, engineering controls,

administrative controls, personal protective equipment and

emergency procedures.

When and how to report leaks and spills.

Where to get more information.

Consider a system for documenting employee training. For example,

employees could sign a form to verify that they attended the training

and understand the company’s hazard communication policy. This is

not a requirement but is a recommended option for your program.

Follow up after training sessions. Be sure that employees know how

to handle chemicals and are using the training they were given. When

your employees use protective equipment, be sure to keep it clean and

properly maintained. Make certain it is available to your employees

and they are using it.

15

Follow each chemical from storage through use to disposal.

Determine which employees are or could be exposed to it.

Review your existing methods for controlling exposure to

hazardous substances. The best method is to eliminate the

hazard at the source. If elimination is not possible, control

the hazard at its source with engineering controls, or limit

worker exposure using administrative controls. If these

two methods are not enough to remove or reduce the

worker exposure to acceptable levels, then use personal

protective equipment. List specific procedures for each

work area and substance.

1. Engineering controls, including exhaust ventilation

systems, dust collection systems and process

enclosures.

2. Administrative controls, such as having a standby

person for confined-space entry, rotating employees

to reduce exposure, lockout/tagout procedures and

substituting a non-toxic or less toxic chemical.

3. Personal protective equipment you provide such

as respirators, gloves, boots, aprons, goggles and

face shields.

Review your current chemical handling procedures and

compare them to recommended practices indicated on the

label or SDSs. This will help identify where you may need to

improve your procedures.

List the emergency procedures for each work area and

each substance.

Good emergency response procedures help protect the

safety and health of your employees and reduce the

potential loss of property and equipment.

How to Determine Your Employees’ Exposure to Chemicals

17

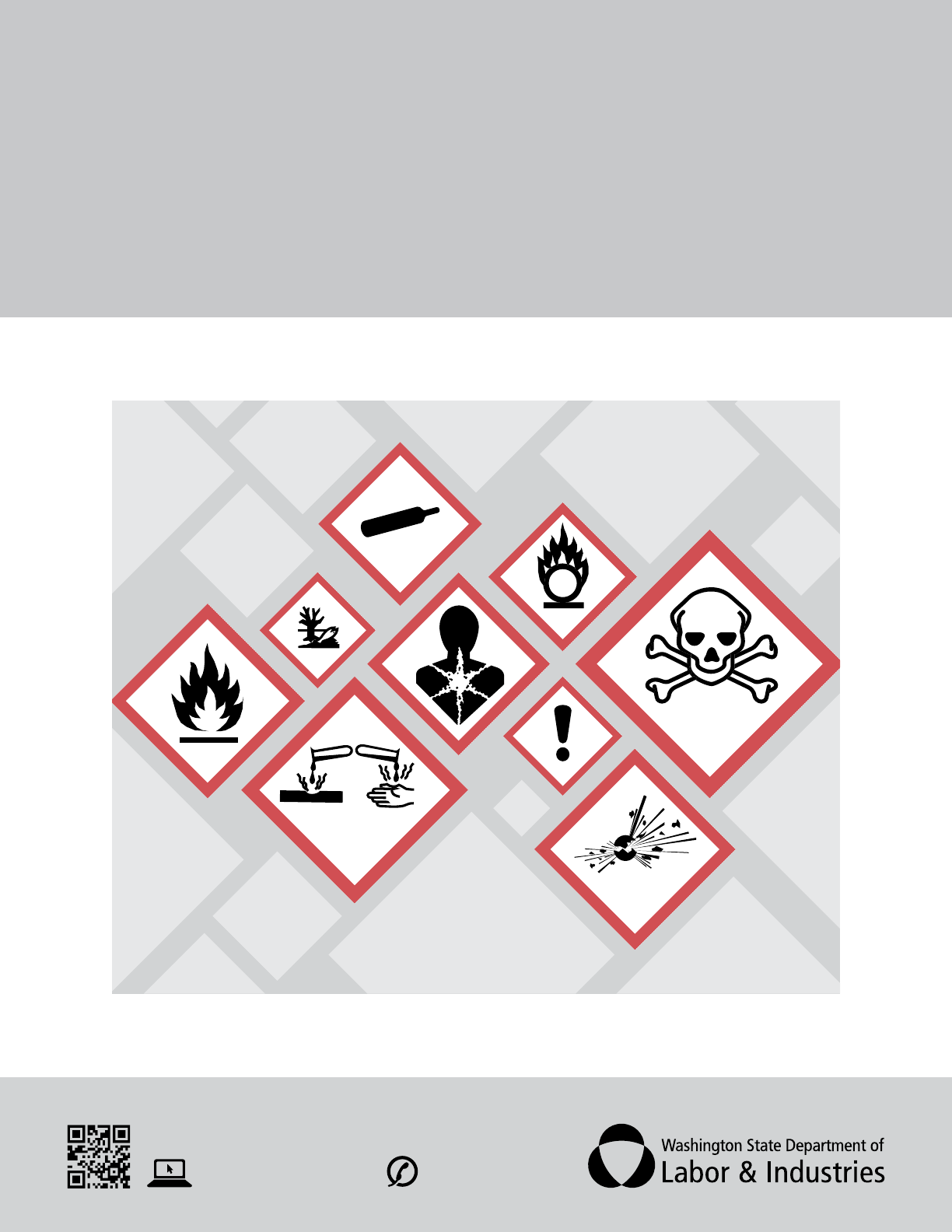

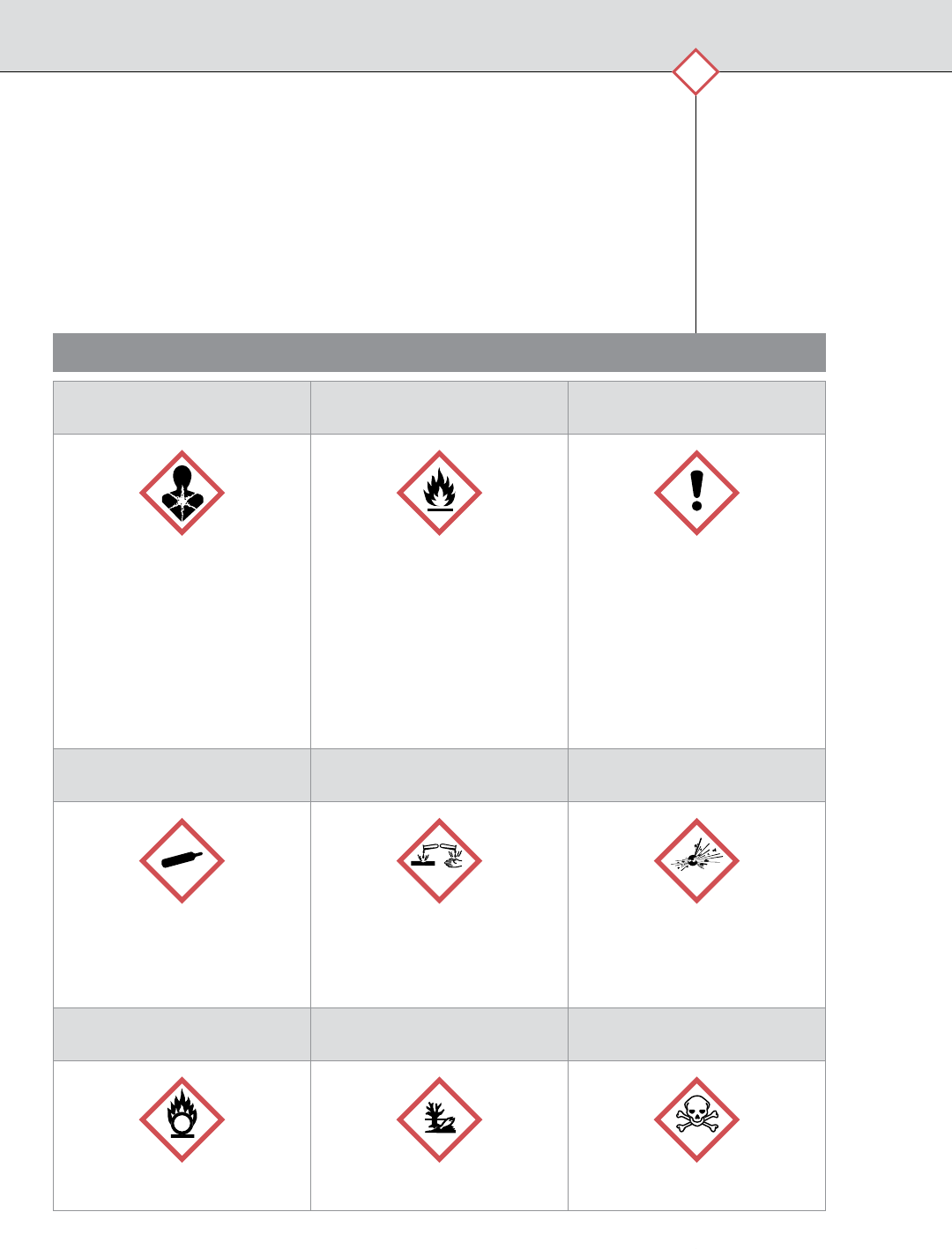

Pictograms

As of June 1, 2015, the Hazard Communication rule will require

pictograms on labels to alert users of the chemical hazards to which

they may be exposed. Each pictogram consists of a symbol on a white

background framed within a red border and represents a distinct

hazard(s). The pictogram on the label is determined by the chemical

hazard classication.

Appendix

HCS Pictograms and Hazards

Health Hazard Flame Exclamation Mark

Carcinogen

Mutagenicity

Reproductive toxicity

Respiratory sensitizer

Target organ toxicity

Aspiration toxicity

Flammables

Pyrophorics

Self-heating

Emits flammable gas

Self-reactives

Organic peroxides

Irritant (skin and eye)

Skin sensitizer

Acute toxicity (harmful)

Narcotic effects

Respiratory tract irritant

Hazardous to ozone layer

(non-mandatory)

Gas Cylinder Corrosion Exploding Bomb

Gases under pressure

Skin corrosion/burns

Eye damage

Corrosive to metals

Explosives

Self-reactives

Organic peroxides

Flame Over Circle

Environment

(Non-mandatory)

Skull and Crossbones

Oxidizers

Aquatic toxicity

Acute toxicity (fatal or toxic)

(From OSHA QuickCard 3491)

18

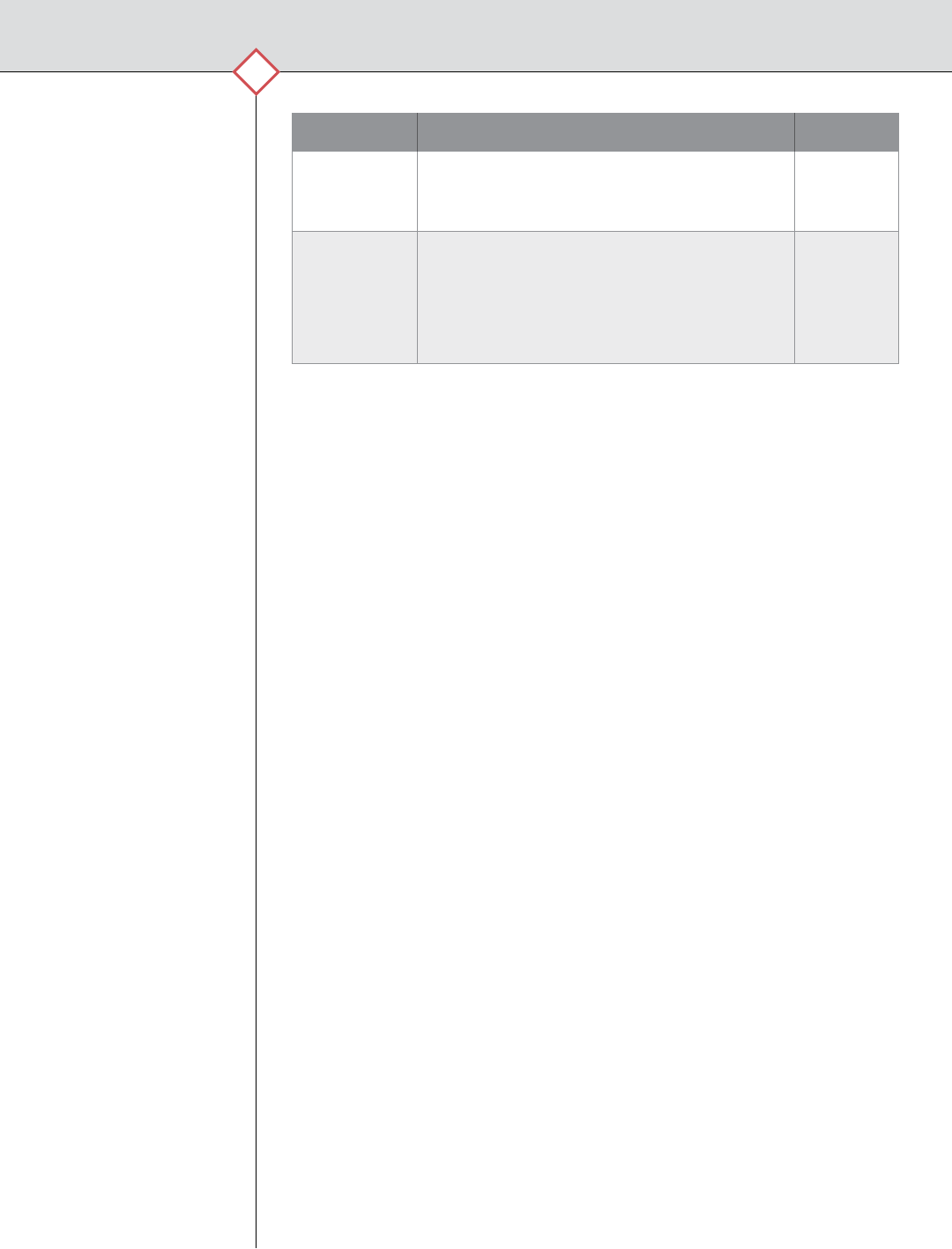

Labels

As of June 1, 2015, all labels will berequired to have

pictograms, a signal word, hazard andprecautionary statements,

the product identier, andsupplier identication. A sample

revised label,identifying the required label elements, is shown

below. Supplemental information can also be providedon the

label as needed.

Supplemental Information

CODE

Product Name

Product

Identifier

Company Name

Street Address

City State

Postal Code Country

Emergency Phone Number

Supplier

Identification

Fill weight: Lot Number:

Gross weight: Fill Date:

Expiration Date:

Directions for Use

Keep container tightly closed. Store in a cool,

well-ventilated place that is locked.

Keep away from heat/sparks/open flame. No smoking.

Only use non-sparking tools.

Use explosion-proof electrical equipment.

Take precautionary measures against static discharge.

Ground and bond container and receiving equipment.

Do not breathe vapors.

Wear protective gloves.

Do not eat, drink or smoke when using this product.

Wash hands thoroughly after handling.

Dispose of in accordance with local, regional, national,

international regulations as specified.

In Case of Fire: Use dry chemical (BC) or Carbon Dioxide (CO

²

)

fire extinguisher to extinguish.

First Aid

If exposed call Poison Center.

If on skin (or hair): Take off immediately any contaminated

clothing. Rinse skin with water.

Precautionary

Statements

Hazard

Statements

Highly flammable liquid and vapor.

May cause liver and kidney damage.

Hazard Pictograms

Signal Word

Danger

Sample Label

(From OSHA QuickCard 3492)

19

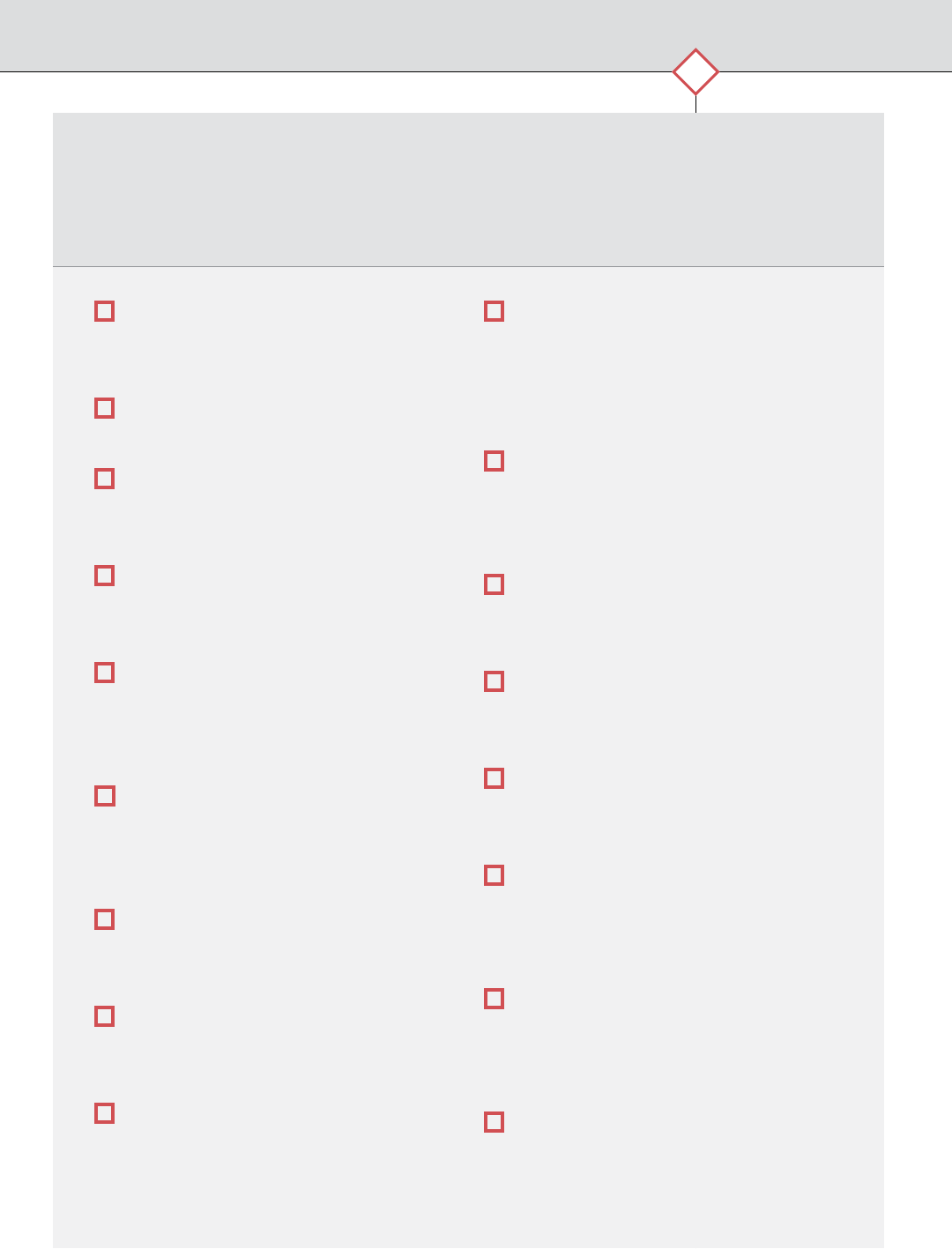

Safety Data Sheets

A safety data sheet (SDS) must include the information specied in the

table under the section number and heading indicated for sections 1–11

and 16. If no relevant information is found for any given subheading

within a section, the SDS must clearly indicate that no applicable

information is available. Sections 12–15 may be included in the SDS,

but are not mandatory.

(Adapted from OSHA QuickCard 3493)

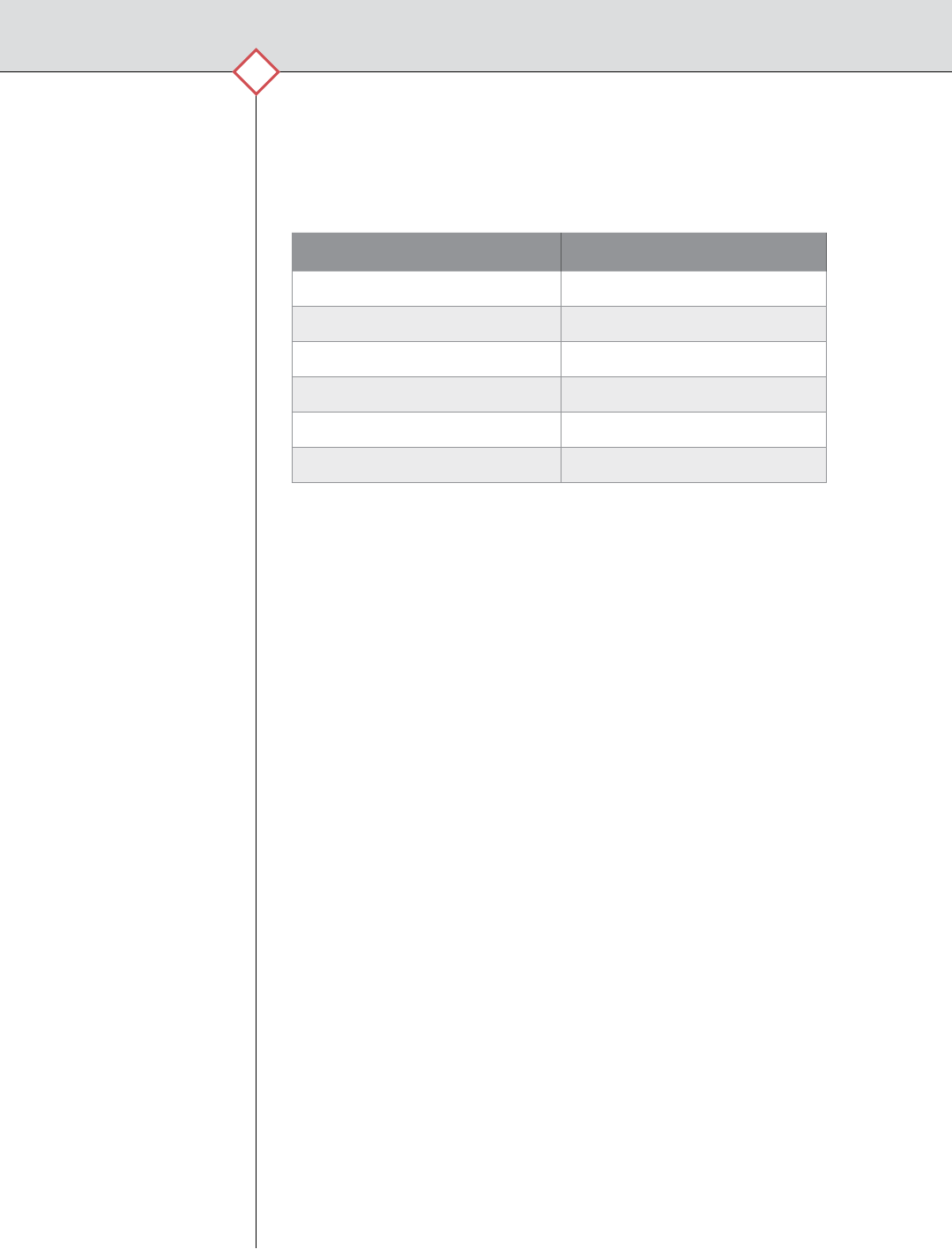

Section Heading Relevant Information

Section 1 Identification Includes product identifier;manufacturer or distributor name,

address, phone number; emergency phone number; recommended

use; restrictions on use.

Section 2 Hazard(s) identification

Includes all hazards regarding the chemical; required label elements.

Section 3 Composition/information on

ingredients

Includes information on chemical ingredients; trade secret claims.

Section 4 First-aid measures Includes important symptoms/effects, acute, delayed; required

treatment.

Section 5 Fire-fighting measures Lists suitable extinguishing techniques, equipment; chemical

hazards from fire.

Section 6 Accidental release

measures

Lists emergency procedures; protective equipment; proper methods

of containment and cleanup.

Section 7 Handling and storage Lists precautions for safe handling and storage, including

incompatibilities.

Section 8 Exposure controls/

personal protection

Lists Permissible Exposure Limits (PELs); Threshold Limit Values

(TLVs); appropriate engineering controls; personal protective

equipment (PPE).

Section 9 Physical and chemical

properties

Lists the chemical’s characteristics.

Section 10 Stability and reactivity Lists chemical stability and possibility of hazardous reactions.

Section 11 Toxicological information Includes routes of exposure; related symptoms, acute and chronic

effects; numerical measures of toxicity.

Section 12 Ecological information Non-mandatory

Section 13 Disposal considerations Non-mandatory

Section 14 Transport information Non-mandatory

Section 15 Regulatory information Non-mandatory

Section 16 Other information Includes the date of preparation or last revision.

20

The Department of Labor & Industries will help you meet the

requirements of the Hazard Communication rule. For assistance,

contact the nearest L&I ofce and ask to speak to an Industrial

Hygiene Consultant, or visit www.Lni.wa.gov/Safety/Consultation .

Business Location Call

Northwest Washington 425-290-1431

King County 206-515-2837 or 206-835-1146

Pierce County/Olympic Peninsula

253-596-3917

Southwest Washington 360-902-5472

Central Washington 509-886-6570

Eastern Washington 509-324-2543

For more information on Hazard Communication, visit

www.Lni.wa.gov/Safety/Topics/AtoZ/GHS .

Where to Get Help

PUBLICATION F413-012-999 [07-2014]

Upon request, foreign language support and formats for persons

with disabilities are available. Call 1-800-547-8367. TDD users,

call 360-902-5797. L&I is an equal opportunity employer.